一种用双层凹模补偿U形弯曲回弹的模具优化方案

打开文本图片集

中图分类号:TG241 文献标志码:B

A mold optimization scheme for compensating U-shaped bendingspringbackwithadouble-layer die

SHU Jiangjiao’ ,SHU Junping²,JING Longjian³, ZHAO Song2 ,YAN Qiufeng

(1. School of Electrical Engineering and Automation, Nantong University,Nantong Jiangsu 226O19,China; 2. Zhejiang YiLiDa Science And Technology Co. Ltd.,Taizhou , China; 3. Songbo Electric(Shanghai) Co. Ltd.,Shanghai ,China)

Abstract: This study focuses on a distinctive motor support product. Through detailed process analysis,the development shape and forming force were calculated. The setting of critical dimensions leads to fluctuations in the size chain, particularly affecting high-side-wall U-shaped bending parts which are prone to springback. By employing upsetting pressure correction and side-pressure roof structures,the impact of springback is effectively mitigated. The innovative introduction of a doublelayer concave die,combined with gradual deformation,appropriate die material selection,and TD treatment, transitions the bending gap from large to normal until the final upsetting pressure correction. This approach cleverly alleviates complex deformations caused by bending of the reinforcing bar at the bottom of the connected side wall,thereby further controlling springback. Mass production verification has confirmed that this mold efectively addresses production challenges and provides innovative solutions for similar products. Key words: processability analysis; upsetting correction; side pressure ceiling; double-layer die;slow deformation

0 引言

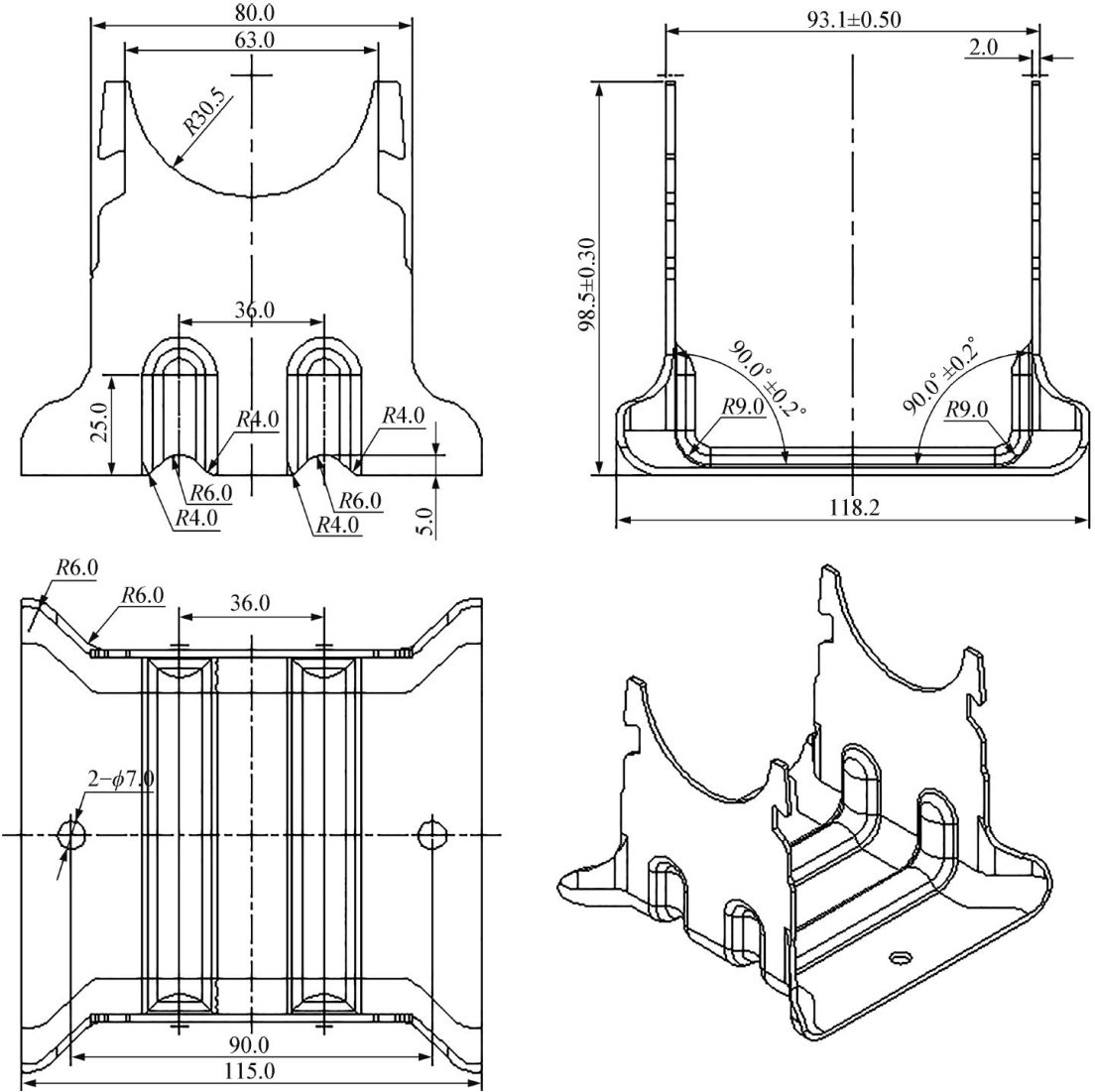

图1是经多次试样优化后的电机支架产品图,材质为SPCC,材料厚度 T=2.0mm 。(剩余8362字)