Ti6554合金铸锭挤压工艺研究

打开文本图片集

中图分类号:TG376.2;TG376.8 文献标志码:A

文章编号:1001-4934(2025)03-0054-06

Research on extrusion process of Ti6554 alloy ingot

GAO Zhanghu', SONG Liping1, SUN Hui1,XU Guangsheng1²

(1. Shaanxi Polytechnic Institute,Xianyang 712OOo,Shaanxi,China; 2. Engineering Research Center of High-performance Aerospace Materials and Devices in Universities of Shaanxi Province, Xianyang 712ooo, Shaanxi, China)

Abstract: In this paper, the influences of extrusion temperature and extrusion ratio on the microstructure and properties of a new type of small-sized β titanium alloy Ti6554 bar during extrusion were explored. By manipulating different processing parameters, the internal microstructure and the factors affecting the material properties were analyzed. The results indicate that the grains of the alloy are refined significantly at a higher extrusion ratio and a more appropriate extrusion temperature, thereby enhancing the mechanical strength and overall performance of the material. In this study, to concurrently consider the degree of grain refinement after extrusion and the mechanical properties at room temperature and avoid small deformation during utilization, the optimized extrusion process parameters of Ti6554 titanium alloy are as follows:extrusion temperature 1080∘C ,extrusion ratio 4,and extrusion speed 30~45mm/s

Key words: Ti6554;extrusion temperature; extrusion ratio; organizational performance; tensile fracture analysis

0 引言

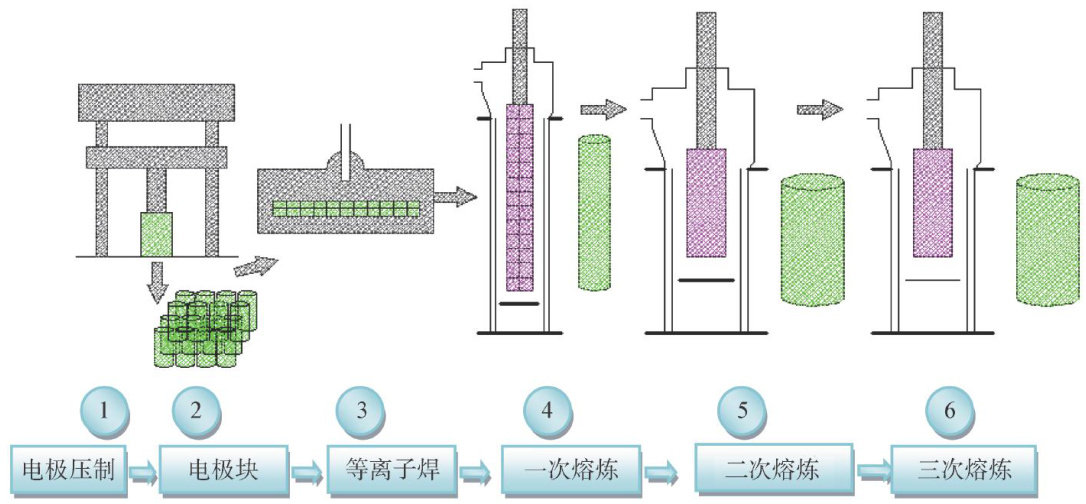

Ti6554是宝钛集团近年来研发的一种高强高韧 β 钛合金,具有较高的疲劳强度和抗裂性,同时保持了较低的密度,这使其在制造飞机结构部件、高性能汽车零件以及要求极高耐久性的应用中尤为重要[1]。(剩余5085字)