铝合金扩散连接技术与界面质量调控方法研究进展

打开文本图片集

中图分类号:TG457.14 文献标志码:A

文章编号:1001-4934(2025)03-0094-11

Research progress on diffusion bonding technology and interface quality control methods of aluminum alloys

CHENYao1,JIANGSengbao1*,RONGJian1,WANGYushengPU Rongseng' ,LI Xifeng²,WANG Zengyu²

(1. Chengdu Aircraft Industrial (Group) Co. Ltd, Chengdu 61OooO Sichuan,China; 2. School of Materials Science and Engineering,Shanghai Jiao Tong University, Shanghai ,China)

Abstract: As an important light-weight and high-strength metal material, aluminum alloy has been widely used in aerospace,automobile,ship and other fields. As an advanced solid-state welding method,diffusion bonding technology has a broad application prospect in the field of aluminum alloy connection because of the advantages of high strength,small heat-affected zone and small deformation. However,the interface quality control in the process of diffusion bonding has always been difficult in the application of this technology. The dense and stable oxide film has been exist in the surface of aluminum alloy,which seriously hinders the diffusion bonding process,and then affects the quality of the diffusion joint. Breaking through the problem of diffusion bonding of aluminum alloys can provide a solid foundation for the broad application of superplastic forming and diffusion bonding (SPF/DB) technology. Based on the research progress of aluminum alloy diffusion bonding technology and interface quality control methods at home and abroad, this paper systematically analyzes the influence factors of aluminum alloy and aluminum-magnesium dissimilar alloy diffusion bonding and postwelding heat treatment,and prospects the application prospect and future research direction of aluminum alloy diffusion bonding technology in aerospace field.

Key words:aluminum alloys;diffusion bonding;oxide film;interface quality

0 引言

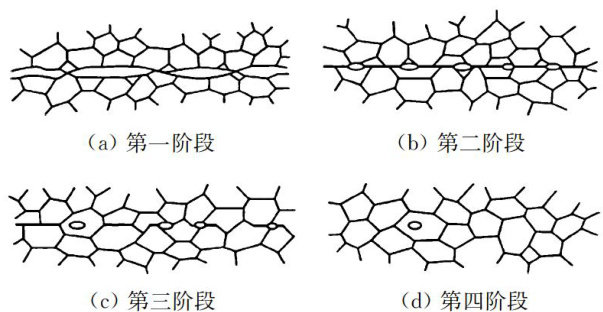

铝合金具有低密度、高弹性模量、高比强/比刚度等优点,作为结构材料被越来越多地应用于航空航天等多个领域[1],并已广泛用于需要减重、中等强度和耐腐蚀性的结构件中,例如机身大梁、桁架、支柱和直升机旋翼部件2]。(剩余17039字)