机车制动盘螺栓安全性分析研究

打开文本图片集

中图分类号: U270.35+1 文献标志码:B doi:10.20214/.cnki.zhdt.2025.01.0

SafetyAnalysisandResearchonLocomotiveBrakeDiscBolt

HUANGMingao,WANGShoubing,XIONG Wenhua,SHENQiangjun,HUANGX (CRRCZhuzhouElectricLocomotiveCo.,Ltd.,Zhuzhou,China)

Abstract:The mechanical properties,chemicalcomposition,hardnes,fracture morphology and metalographyofdomesticboltsforlocomotivebrakediscs weretestedandanalyzed.The mechanical properties,chemicalcompositionandhardnes ofbrokenboltsalmettherequirementsofrelevantstandards. Thefracturemorphologyandmetalographictestingindicatedthatitwasafatiguefractureresultingfromthe loseningofboltsduringservice.ThetheoreticalcalculationiscariedoutacordingtoGermanVDI230 standard,andtheresultshowedthatthedesignandselectionofbrakediscboltsmettherequirements. Meanwhile,thefrictioncoeficientoftwodomesticbrakediscboltsandKnor brakediscboltswastestedand comparedwiththetestequipment.Itwasfoundthatheendfacefrictioncoeficient,threadfrictioncoeficient andasemblypreloadofbrakediscboltsprovidedbyKnor weretheclosesttothetheoreticalcalculation values,whiletheendfacefrictioncoeficientandthreadfrictioncoeficientofdomesticsuplier2wereto large,andtheasemblypreloadwasto smal,resultingintheloseningandbreakingofbrakediscboltsin service.Finaly,thesethre brakediscboltshavebentestedforresidualtorqueandthetighteningprocesis optimized.

Keywords:brakedisc;VDI230;frictioncoeficient;residualtorque;torquedecay

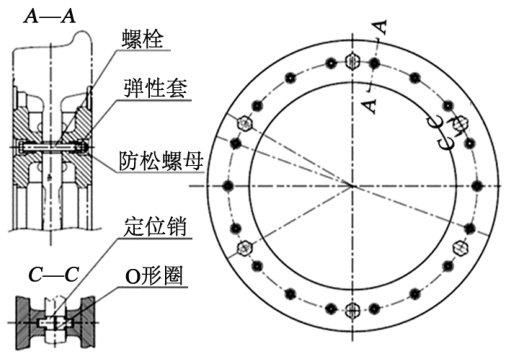

机车制动盘安装由制动盘、定位销、弹性套、螺栓、防松螺母、O 型圈等主要零件组成(图1),制动盘为整体盘,在摩擦面的反面铸有散热筋。(剩余4701字)