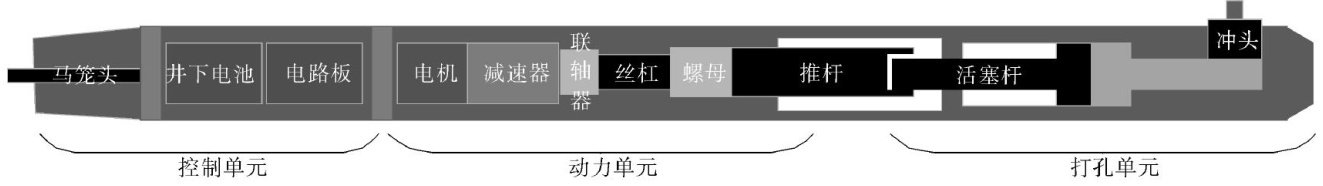

井下电动油管打孔工具研制

打开文本图片集

中图分类号:TE934.05 文献标志码:B doi:10.3969/j.issn.1001-3482.2025.05.012

文章编号:1001-3482(2025)05-0078-07

Abstract:In the process of oilfield production,poor tubing and casing connectivity often leads to reduced production.Traditionally,the perforation technology using gunpowder has been employed to restore connectivity.However,this method is prone to causing damage to the casing.In view of this, based on the modular design concept,a downhole electric tubing puncher was innovatively developed. This tool utilized an electro-hydraulic thrust system and was capable of achieving precise punching operations on the tubing.Through this approach,while effectively enhancing the tubing and casing connectivity,it successfully preserved the structural integrity of the casing,avoiding a series of subsequent problems caused by casing damage. Verified by experiments,this downhole electric tubing puncher exhibited excellent performance and effects,providing solid technical support for subsequent production increase operations in the oilfield and possessing remarkable technological innovation and broad application prospects.

Key words: electric tool; structural design; tubing punching; experimental test

随着油气田开发进入中后期,蜡沉积、垢层形成以及砂粒堵塞等复杂因素导致油套环空连通性显著下降,严重影响油井的生产能力[1-5]。(剩余6285字)