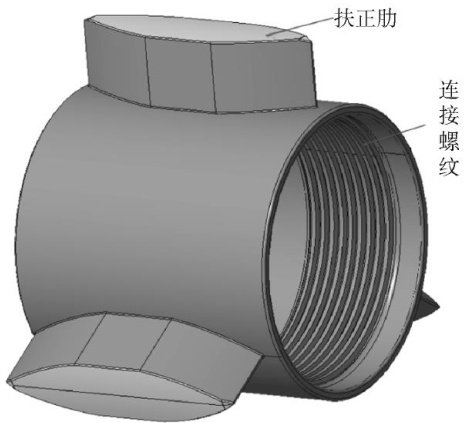

旋转导向钻井系统用探管扶正器设计研究

打开文本图片集

中图分类号:TE921.2 文献标志码:A doi:10.3969/j.issn.1001-3482.2025.05.006

Abstract: The rotary steerable drilling system is a widely used directional drilling technology system at present.The centralizer of the probe pipe is a key mechanical part of it.Its main function is to keep the measurement module inside the instrument centered and fixed in the mud flow channel,reducing the influenceof the instrument’s vibration in the wellon the measurementresults.At the same time,it neds to minimize the influence of the centralizer's ribs on the pressure of the fluid in the flow channel. According to the functional requirements for the centralizer of the probe pipe,a three-rib centralizer structure for the probe pipe was designed.The full three-dimensional numerical simulation was carried out by using the CFD method.The flow field situation when the fluid passed through the centralizer’s ribs was analyzed,and the pressure loss of the fluid flowing through the centralizer of the probe pipe was calculated.Based on the analysis results,the structure of the centralizer's ribs was improved.The research finds that the flow lines are relatively chaotic,and there is acertain pressure loss when the fluid passes through the centralizer's ribs.Alarger displacement and higher mud ratio indicate a greater total pressure loss.Through the analysis of function and working environment,the material selection and structural finalization of the centralizer of the probe pipe are completed,and the centralizer of the probe pipe is finally developed.

Key words:rotary steering; three-rib centralizer; fluid simulation; numerical simulation; optimal design

随着我国油气勘探开发向着深水、深层及非常规油气进军,水平井、大位移井的广泛应用,旋转导向钻井技术得以蓬勃发展,该技术能够在旋转钻井过程中,控制钻井轨迹,精确导向进入油层的最佳位置,是目前实现定向钻井的高端系统,油气开发效率和开发能力可以得到大幅提升[1-5]

在钻井过程中,旋转导向仪器内测量模块需要进行仪器姿态测量,其包含的加速度表、陀螺仪与磁通门等测量元器件分别对井斜、方位、转速进行实时监测与上传,因此在测量过程中就需要避免测量模块自发的振动[。(剩余5272字)