用于3D打印的固废材料配合比设计及性能研究

打开文本图片集

中图分类号:U416.1 文献标志码:A 文章编号:1005-8249(2025)04-0039-07

DOI:10.19860/j.cnki.issn1005-8249.2025.04.008

DENG Jingxiang',WANG Zhenkun’,NIU Like²,CHEN Peng²,HE Bo’,CHEN Junwei²,HUI Bing²(1.Gezhouba Group Transportation Investment Co.,Ltd.,Wuhan 43OOOO, China;2.Shandong Transportation Research Institute, Ji' nan 25O1O4, China)

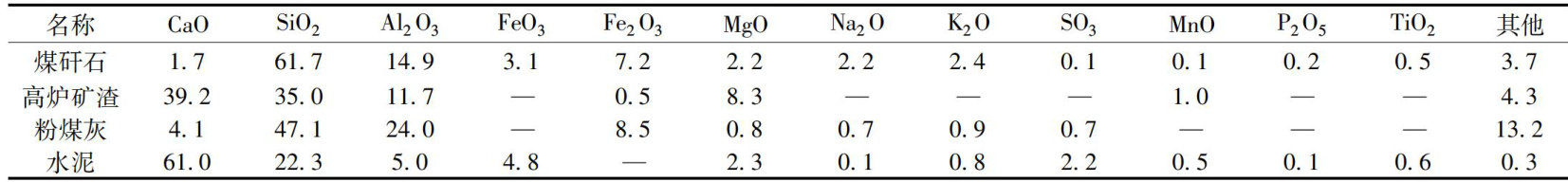

Abstract:Inorder toreducecarbonemisions duringhighwayconstruction,the applicationofsolid waste materials such as coal gangue,blastfurnaceslagandflyashin3Dprintingtechnologyisrealized.Thispaperstudiesthedesignandperformanceof multi-sourcesolid wastematerialsbasedon3Dprinting technologyTheefectsofflyashcement massratio,water-binder ratio,sand-binderratioand waterreducerontheprintability,buildability,physicaland mechanical propertiesanddurability of materialsareanalyzed.Theresultsshowthatthewater-binderratioandwaterreducerare themainfactorsaffecting the fluidityofsolidwastematerials,whicharepositivelycorrelatedwiththefluidity;Theheightchangerateandcompressive strengthof theprinting material decreasewiththeincreaseofwater-binderratio,the water-binderratioshouldbeO.35;The massratioofflyashtocementisnegativelycorelatedwithcompressivestrength,themassratioofflyashtocementshouldbe (204号 10:90 ;Withtheincreaseofsand-binderratio,thecompresive strengthof printing materials increases firstand thendecreases, andthepeak pointappearsat1.2;Thedurabilityofsolid wastematerialis negativelycorelated withtedosageofwaterreducing agent,the dosage should not exceed 1% .The research results can provide reference for the design and application of similar 3D

printingmaterials.

Key Words:3d printing; solid waste materials; mix proportion; printing properties; influencing factor

0 引言

随着我国智能建造技术日新月异的高速发展,新兴3D打印技术。(剩余7418字)