钢渣粉-矿渣粉复合胶凝材料力学性能的研究及预测

打开文本图片集

DOI:10.19860/j.cnki.issn1005-8249.2025.04.001

WANG Yifei14,WAITI Litipu², JI Haojie14,LIU Zunqing1,3,4 (1.School of Trafic and Logistics Engineering, Xinjiang Agricultural University, Urumqi 830o52,China; 2. Xinjiang Transportation Investment and Construction Management Co. Ltd., Urumqi 830OOO,China; 3. College of Hydraulic and Civil Engineering, Xinjiang Agricultural University, Urumqi 83O052,China; 4. Xinjiang Road Engineering Test and Inspection Research Center (Xinjiang Agricultural University Road Engineering Research Center),Urumqi 830O52,China)

Abstract:Tosystematicallyinvestigate theevolutionlawof mechanical propertiesof steeslag powder-slagpowdercomposite cementitious materials,mortar specimens were preparedusing diferent proportionsof slag powder,steel slag powder,and cement,andtheirflexuralandcompresivestrengthswere testedatcuringagesof1,3,7and28days;BPneuralnetworkand random forestmodelswere furtherestablished topredictthelater mechanicalpropertiesof thecompositecementitiousmaterial.

材料科学

The results showed that when 10% steel slag powder and 30% slagpowder were added,the mechanical properties were excellent,with flexural strength reaching 12. 22 MPa and compressive strength reaching 50.10MPa at 28 days;The prediction accuracyoftheBPneural networkwassignificantlysuperior tothatof therandom forest model,withmeanabsoluteerror ( MAE ),root mean square error(RMSE),and coeficient of determination ( R2 )for compressive strength prediction being 1.823,2.136andO.956,respectively.This studyprovidesareliable methodfor predicting the performanceof industrial solid waste-basedcementitious materialsandofers theoreticalbasisandreference for promoting theapplicationof greenand lowcarbon building materials.

Key words: steel slag powder; slag powder; BP neural network;random forest; strength prediction

0 引言

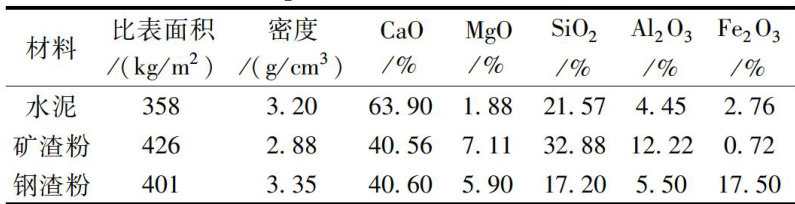

我国水泥产业在快速发展的同时,也面临着石灰石资源日益紧缺和市场价格持续上涨的双重挑战。(剩余5759字)