不同掺合料对3D打印复合浆体流变性能的影响

打开文本图片集

中图分类号:TU52 文献标志码:A 文章编号:1005-8249(2025)03-0068-05

DOI:10.19860/j.cnki.issn1005-8249.2025.03.013

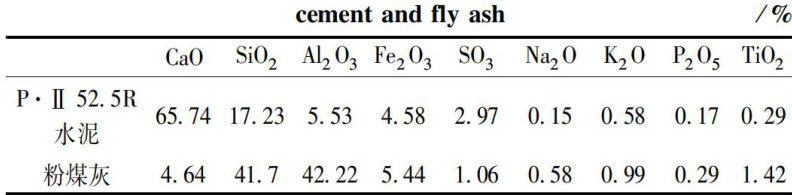

Abstract:Theefectsofsingleaditionofsilicafume,flyash,mineralpowderandtheirmutualblendingontherheological propertiesandconstructabilityof3Dprintingcompositeslurywere investigated.Theresultsshowthatthe staticyieldstresof theslurywithsingleadditionofflyash,mineralpowderandsilicafumegraduallyincreaseswiththeincreaseoftheadition amount.Withtheincreaseof theadditionamountofflyashandmineralpowder,thecylindercollpsedegreeandfluidityofthe slurry showanincreasing trend,whiletheadionofsilicafumeshowstheopposite trend.Whenthethreeare addedmutually, the possible rules may be different from those of single addition. When 4% silica fume is added singly,the yield stress and fluidity are good;when 5% mineral powder is added singly,the effect is the best;when 30% fly ash isadded singly,the rheological propertiesofthesluryarethebest.Whenthethreeareaddedmutually,therheologyandconstructabilityof the3D printing composite slurry are the best when the addition amount of silica fume is 4% ,the addition amount of mineral powder is 5% ,and the addition amount of fly ash is 10% :

Key words: silica fume; fly ash;mineral powder; compound addition; rheological property

0 引言

3D打印混凝土可打印性能的表征和优化为当下的研究热点之一。(剩余6476字)