船舶大构件几何特征建模及装配干涉检测方法

打开文本图片集

关键词:装配特征识别;快速建模;船舶大尺度构件;肋板拉入装配;精度检测 中图分类号:U671.99 DOI:10.3969/j.issn.1004-132X.2025.07.026 开放科学(资源服务)标识码(OSID):

Geometric Feature Modeling and Assembly Interference Detection Method for Large Ship Components

GU Shimin1 LIU Jinfeng1,* QIAN Tianlong² JING Xuwen1 WANG Xuemin² MAO Baochen1SHEN Yang² CHEN Yu1 1.Jiangsu University of Science and Technology,Zhenjiang,Jiangsu,212000

2.COSCO Shipping Heavy Industry(Yangzhou) Co.,Ltd.,Yangzhou,Jiangsu,225200

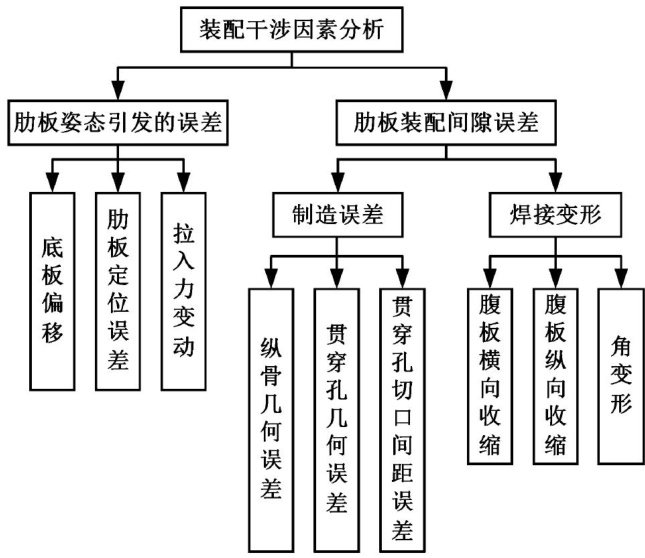

Abstract: Manufacturing errors and welding deformations in manufacturing and assembly of ship components affected the success rate and eficiency of rib plate puling-in assembly. Therefore,a rapid modeling and assembly interference detection method for large ship components was proposed based on geometric features. The method defined assembly features, used the improved ASPacNet to accurately identify the assembly features,carried local reconstruction and splicing out,and detected assembly interference through a time-domain intermittent fit clearance calculation method. Experiments show that the modeling efficiency of the method for large ship components is 66.01% higher than that of traditional methods,the root mean square error of modeling is as 0.206mm ,and the interference detection accuracy reaches 98.81% . It may effectively reduce trial assembly and provide a new technical means for the efficient assembly of large ship components.

Key words: assembly feature recognition; rapid modeling; large-scale components of ship;rib pull-in assembly;precision detection

0 引言

大型船舶的生产大多采用分段建造法,即在工艺设计阶段将船体分段,分段制造车间生产所需分段,并于船台完成分段的合拢和总装,从而完成全船的建造。(剩余20831字)