机理与数据融合驱动的复杂航空复材部件关键装配误差元素辨识方法

打开文本图片集

关键词:机理模型;数据驱动;灵敏度分析;机理-数据融合建模;复材装配中图分类号:V262DOI:10.3969/j.issn.1004-132X.2025.07.016 开放科学(资源服务)标识码(OSID):

Identification and Evaluation of Key Error Elements in Complex Composite Aviation Componts Assembly Driven by Mechanism and Data Model Fusion

GUO Feiyan1*ZHANG Hui²SONG Changjie1ZHANG Shuo¹ 1.School of Mechanical Engineering,University of Science and Technology Beijing,Beijing,100083 2.AVIC Shenyang Aircraft Industrial(Group) Co.,Ltd.,Shenyang,110850

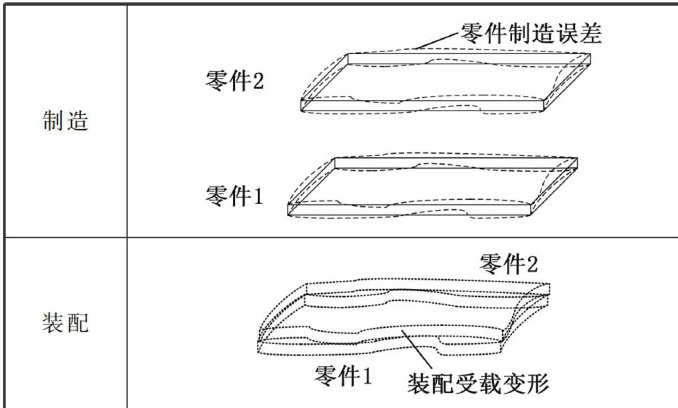

Abstract: In composite assembly of complex aviation products, the factors such as part deformations under loads, numerous parameters and so on were considered. Deformation error source models for key assembly links caused by positioning and clamping,joining and rebounding were analyzed,and the Jacobian sensor matrix representing error transmisson relationship was modified to establish assembly error transmission mechanism model. A support vector regression model was established based on assembly error data,a fusion model of mechanism model and data model was gained.With the predication and compensation model for the calculated values of the error mechanism model and the actual deviation,a Sobol sensitivity analysis method was adopted to calculate the global sensitivity coefficients of different assembly error links,and the key error elements affecting assembly accuracy was identified.Finally,the assembly of wing box component was taken as an example to prove the effectiveness of the proposed method.

Key words: mechanism model; data driven; sensitivity analysis;mechanism-data fusion modeling;composite assembly

0 引言

装配作为高端产品制造的最终环节,在生产效率提升与服役性能保障中具有重要意义[1]。(剩余23369字)