304不锈钢极薄带微流道气胀成形材料流动行为及微观组织

打开文本图片集

中图分类号:TG39

DOI:10.3969/j.issn.1004-132X.2025.07.003 开放科学(资源服务)标识码(OSID):

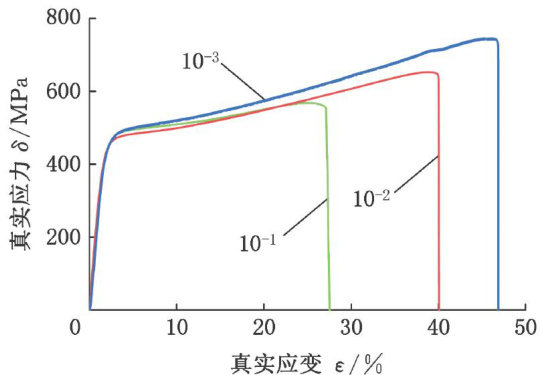

Abstract: Microchannel gas forming experiments and numerical simulations on 304 stainless steel ultra-thin strips were conducted. Stress distribution,strain distribution,and thickness Variation patterns at diferent locations of the blanks in forming processes were investigated. The evolution mechanism of the microstructure at typical positions of the gas formed specimens was analyzed. The comparison between experimental and simulated channel profiles was performed to validate the reliability of the numerical simulation results. The results show that under 25MPa and room temperature conditions,the thickness at the upper fillet decreases from 100μm to 84.05μm ,identifying the region is easy to rupture in forming. The simulated channel depth was as 619.67μm ,while the experimental depth was as 556.34μm . Post-forming analyses reveal that grain size reduces,dislocation density increases,and low-angle grain boundaries raised from 58.04% to 62.61% ,which demonstrate the significant work hardening effects.

Key words:304 stainless steel ultra-thin strip;gas forming;micro-channel; material flow behavior;finite element numerical simulation

0 引言

器件微型化和功率密度最大化已成为光电子器件及新能源行业的发展趋势,微型金属零部件的需求爆发式增长[1-2]。(剩余9101字)