数控机床可靠性的故障模式、影响及危害分析研究现状及发展趋势

打开文本图片集

中图分类号:TG659

DOI:10.3969/j.issn.1004-132X.2025.07.005 开放科学(资源服务)标识码(OSID):

Research Status and Development Trends of Failure Modes,Effects,and Criticality Analysis for CNC Machine Tool Reliability

TIAN Hailong1'² SUN Yuzhi1'² YANG Zhaojun1,2 LIU Zhifeng1,2 CHEN Chuanhai1,2 * HE Jialong1,2

1.Key Laboratory of CNC Equipment Reliability,Ministry of Education,Jilin University, Changchun,130022

2.School of Mechanical and Aerospace Engineering,Jilin University,Changchun,130022

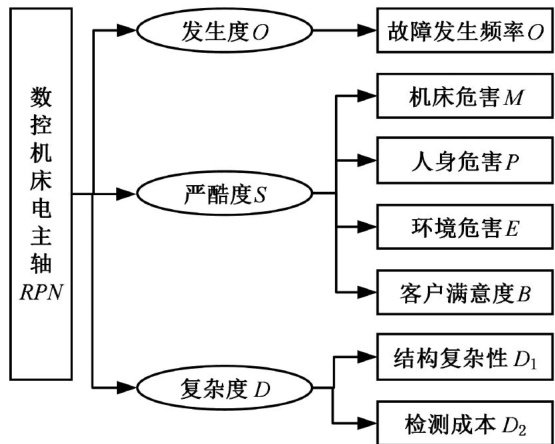

Abstract: FMECA played an important role in reliability maintenance of CNC machine tools. Current researches focused on 4 aspects:comprehensive evaluation of multiple factors, integration of multi-source hierarchical information,integration of multiple analysis methods,and dynamic characteristic modeling. By systematically combination of existing research results,the advantages and existing problems of the 4 aspects were analyzed.Evolution path of machine tool failure modes,effects and criticality analysis were explained by the integration of the characteristics of industrial needs, which provides a theoretical basis for building a high-precision machine tool reliability evaluation system.

Key words: CNC machine tool;reliability analysis; failure mode,effect,and criticality analysis (FMECA);research status

0 引言

数控机床作为现代制造业的核心装备,其可靠性直接制约生产系统的效能与经济性[1-4]。(剩余27562字)