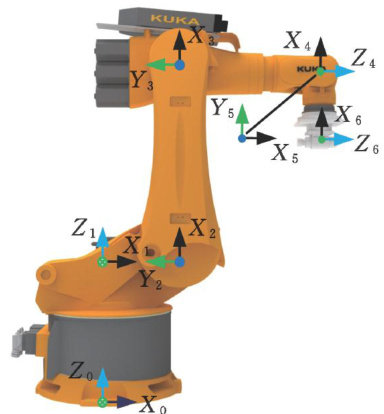

基于最大刚度原则的铣削机器人位姿确定方法

打开文本图片集

关键词:机器人铣削;刚度;加工精度;冗余角

中图分类号:TP242.2

DOI:10.3969/j.issn.1004-132X.2025.07.017 开放科学(资源服务)标识码(OSID):

A Determining Method for Milling Robot Poses Based on Principles of Maximum Stiffness

YI Yali1,2 * CHENG Yangyang² CHEN Xiaowei² CHEN Yifan² ZHANG Zhendong² JIN Herong1,2 1.State Key Laboratory of Crane Technology,Yanshan University,Qinhuangdao,Hebei,066004 2.School of Mechanical Engineering,Yanshan University,Qinhuangdao,Hebei,066004

Abstract: To address the issues of low machining accuracy during slot milling in robot weak-stiffness poses,a robot pose determination method was proposed based on maximum stiffness principle. Firstly,the stiffness was obtained through joint stiffness identification experiments. Then,the stiffness distribution in working plane was analyzed by stifness-oriented evaluation indices,and the optimal robot milling poses were solved based on the maximum stifess principle. Finally,end-loading and milling tests were carried out. The results show that the minimum end-effector comprehensive deformations are as 92μm and 63μm at the milling heights of 1.6m and 1.2m respeclively. After pose optimization,the milling vibration amplitude is reduced by up to 60.88% ,and the maximum wall thickness error is only 40μm :

Key words: robot milling; stiffness; machining accuracy;redundant angle

0 引言

大型薄壁筒类零件广泛用于航空、航天领域,该类零件具有尺寸大、加工可达性差、刚性弱、加工精度要求高等特征,其加工难度已经超过传统数控机床的加工能力[1-2]。(剩余12721字)