Cf/SiC 复合材料微小孔的钻削加工特性

打开文本图片集

中图分类号:TB332

DOI:10.3969/j.issn.1004-132X.2025.07.023 开放科学(资源服务)标识码(OSID):

Drilling Characteristics of Micro Holes on Cf /SiC Composites

YANG Haotian'HE Wenbo1,2.3ZHAO Guolong1*NIAN Zhiwen'YANG Yinfei1,2.3LI Liangl 1.College of Mechanical and Electrical Engineering,Nanjing University of Aeronautics and Astronautics,Nanjing,210016 2.Yangtze River Delta Intelligent Manufacturing Innovation Center,Nanjing,210014 3.Nanjing Avionics Intelligent Manufacturing Technology Co.,Ltd.,Nanjing,210014

Abstract: Diamond drills were used to drill holes of 0.5mm diameter on Cf/SiC composite materials in vertical direction and parallel direction to the fiber weaving. The effects of drilling method and processing parameters on driling forces,hole quality and tool wear were investigated. Material removal mechanism and tool wear mechanism were studied. The results show that vertical drilling has 30% greater thrust forces, 8% less hole damage factor, 20% greater roundness errors,and less tool wear rate than those of parallel drilling.Delamination defects result in smaller surface roughness of hole walls for parallel drilling than those of vertical drilling. The FOA has a significant impact on the material removal mechanism:when FOA is as 0∘ to 90∘ ,the carbon fibers undergo shear fracture re sulting in better surface quality;when FOA is as 90∘ to 180∘ ,the carbon fibers undergo bending fracture leading to poorer surface quality.

Key words: Cf/SiC composite;drilling;hole quality; fiber orientation angle(FOA);material removal mechanism

0 引言

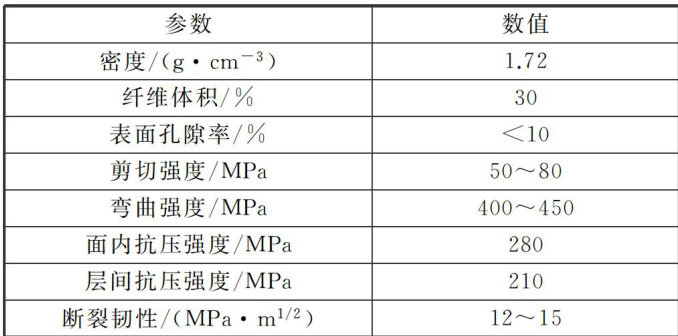

Cf/SiC 复合材料兼具陶瓷的高温耐磨性、化学稳定性,以及碳纤维的高强度和韧性,是一种新型高温结构材料[1-2],由于其轻质、高强、高温稳定、耐磨、耐腐蚀等特点,已广泛用于航天器结构件、热防护系统、高性能制动盘、光学透镜、太阳能反射器、化学反应器等设备[3-4]]

陶瓷基复合材料中的大尺寸孔通常用于连接和装配,微小孔通常具有运输气体和液体的功能[5-6]。(剩余16946字)