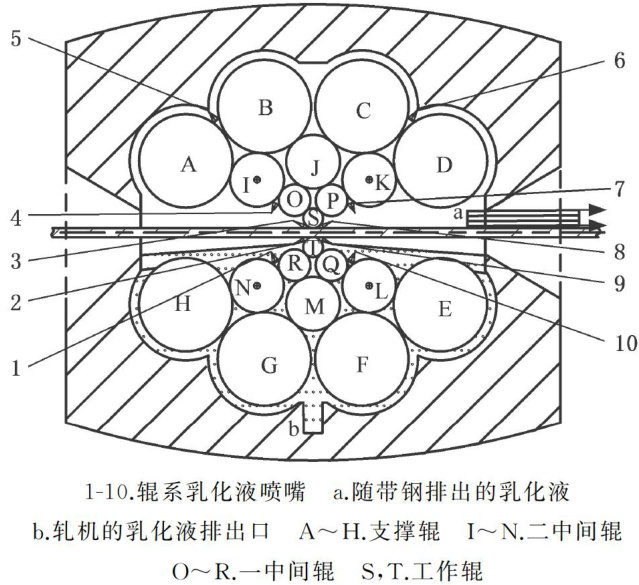

20辊轧机非对称冷却的板形预报模型及影响因素分析

打开文本图片集

中图分类号:TG331 DOI:10.3969/j.issn.1004-132X.2025.07.022

Abstract: Aiming at the edge wave defects in the shapes of finished strip steels produced by 20- high rolling mills,a temperature field calculation method was proposed coupled with multiple boundary conditions and emulsion heat transfer coeficients.A differentiated thermal crown calculation model for upper and lower work rolls in 2O-high rolling mills was established. Mechanics analysis was conducted on the segmented reduction pattern of backup rols,and the deformation coordination relationships in multi-layer rol systems were elucidated. The shape prediction model was developed,which improves computational accuracy by 31.1% ,for precision rolling processes in thin-strip 2O-high rolling mills.The influence patterns of factors, such as original crown difference between upper and lower work rolls,taper configuration of the first intermediate rolls,and backing bearing reduction of backup rolls on thin-strip shape formation,were revealed.

Key words:2O-high rolling mill; shape;temperature field;roll crown

0 引言

随着钢铁生产向绿色化和轻量化发展,20辊轧机以其刚度高、压下量大、板形控制能力强的特点而成为高品质薄板带生产的主力,因此20辊轧机板形控制时考虑因素的研究也愈发深人[1-3]。(剩余12813字)