水钢高炉有害元素研究与控制实践

打开文本图片集

Abstract:In order to reduce production costs and optimize the burden structure of the blast furnace, Shougang Shuigang'sblastfurnacehasintroducedaproportionofharmfulelementssuchasZn,K,Na,andPb.Therefore,aspecial study on the properties of these harmful elements and their circulation principles within the furnace has beenconducted. The research focuses on the impactof these harmful elements on the smelting process and the lifespan of Shougang Shuigang's blast furnace.Developing corresponding prevention and control measures to mitigate the harm caused by these elements to the blast furnace is a key priority in the curent ironmaking process at Shougang Shuigang.

Keywords: blast furnace;harmful elements;prevention and control; lifespan

0前言

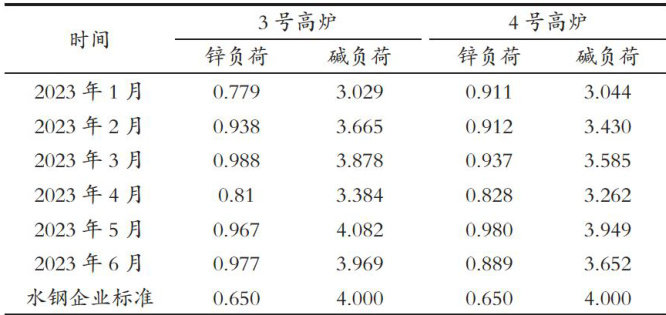

进入2023年,由于钢材市场价格持续低迷,水钢为降低生产成本,优化高炉炉料结构,增加了国内矿的比重:2023年下半年使用进口粉占比较2023年上半年下降了 15.93% ,国内矿粉使用占比上升了 13.03% ,循环资源使用占比上升了 2.90% ,然而经济炉料降低了原料成本的同时,也为高炉带入了有害元素 Zn 、 K 、 Na 、Pb的比重,这些有害元素除按一定规律随炉渣、瓦斯泥、瓦斯灰等物料排出外,还有部分有害元素在高炉的不同温度区间产生循环富集,使炉皮开裂,炉喉及上升管结瘤,对炉衬和高炉其他结构件引起破坏,同时使高炉焦比增加,炼铁成本增加,对高炉的顺行和炉衬寿命造成危害。(剩余3506字)