热作模具钢H13锻造路线对锻件力学性能影响分析

打开文本图片集

ANALYSISOF THEINFLUENCEOFHOTWORKDIESTEEL H13FORGINGPROCESSON THEMECHANICALPROPERTIESOFFORGINGS

Liu YongGao TianZuogWu ZhanJieFeng Hao LuLing (1Wuhu XinxingDuctilleIron PipesCo.,Ltd.Wuhu 241OOo, China)

Abstract: Using forging equipment such as fast forging machines and radial forging machines, diferent forging routecombinations areused toforge hotwork die steel H13underthesame working conditions,and comparison and analysis areconducted basedon each forging experiment data; During the direct forging process of aradial forging machine,the metal mainlyflows inthe axial direction,andthecore forging permeabilityis poor,resulting in poor mechanical properties; When using afast forging and upsetting machine with adiameter forging machine for forming, the performanceoftheforgedmaterialissignificantlyimprovedintermsof tensilestrength,yieldstrength,elongation,poor transverse and longitudinal properties,and notch free impact energy.

Key words : hot work mold steel H13; combination forging route; mechanical performance

0引言

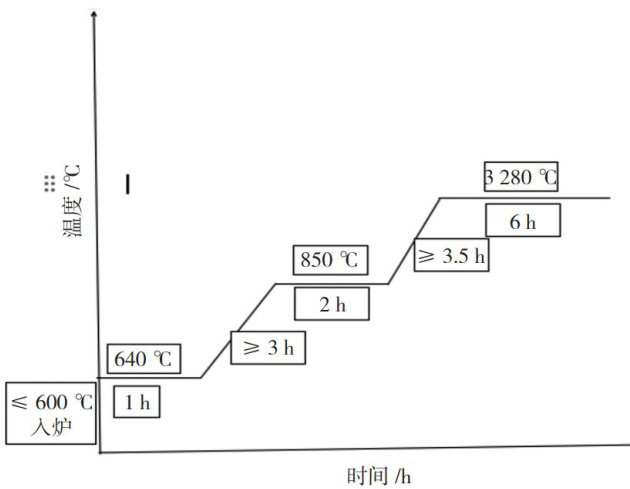

热作模具钢H13(中国牌号4Cr5MoSiV1)是一种常用的中碳铬系热作模具钢,因其优异的高温强度、耐磨性和抗热疲劳性,被广泛用于制造压铸模、热锻模等,其锻造性能受多种因素影响,锻造工艺作为关键制备环节,直接影响材料的最终力学性能。(剩余1596字)