内外协同虚实互补的林业院校“增材制造技术”课程教学改革探索

打开文本图片集

中图分类号:G642 文献标识码:A 文章编号:2095-2953(2025)10-0072-05

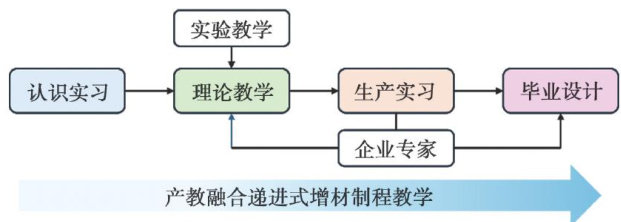

Abstract:Asoneof thecore technologies drivingthenew wave of scientificand industrial revolutions,additive manufacturing(AM)playsa crucial role in cultivating talents essential for implementing the strategyof building a manufacturing powerhouse.However,therapid iteration of AM technologies,the complexityof its knowledge system,and the high cost of advanced manufacturing equipment pose significant challenges to curriculum design and hinder the adequate provision of teaching resources.These factors,in turn,constrain the development of students’practical skillsand inovative capabilities.To adress these issues,this study explores a teaching reform guided by the core philosophyof“internal-external colaborationand virtual-real complementarity.”Byintegrating high-qualityresources from enterprises,research institutes,and partner universities,a colaborative practice teaching communityof “industry-university cooperationand inter-university linkage”has beenestablished,effectivelyovercoming the limitations of on-campus hardware resources.Meanwhile,three-dimensional virtual simulations,remote experimentvideos, and principle animations are combined with hands-on equipment operation to build a multi-level,low-risk practice environment,thus alleviating the chalenges posed by high-cost experiments.Furthermore,a four-stage progressive teaching pathwayof“cognition-theory-practice-innovation”has been developed,with adeep integration of ideological-political education and innovation-entrepreneurship training.Practical results demonstrate that this model significantly enhances students‘learning interest and innovative practiceability,leading toasurge incourse enrollment and multiple awards inacademic competitions.The findings provide a valuable reference for the teaching reformof high-end equipment manufacturing courses under the new engineering education framework.

Keywords:additive manufacturing;talentcultivation;teaching reform

增材制造(又称3D打印)作为先进制造业的新兴前沿技术,以其高效、精准和可定制等优势成为全球制造业关注的热点领域。(剩余5502字)