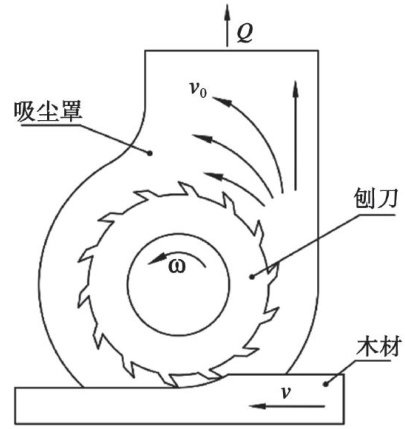

木工四面刨吸尘罩流场分析与结构优化

打开文本图片集

中图分类号:S777 文献标识码:A 文章编号:2095-2953(2025)07-0066-05

Flow Field Analysis and Structure Optimization of Four-side Woodworking Moulder's Suction Hood

HUANG Yong 1,2 ,HAN Yu-heng²*, LIU Jian-qingl (1.SichuanQingchengMachineryCo.,LTD,Meishan Sichuan 62O46O,China; 2.Qingshen Mechanical Industry Research Service Center,Meishan Sichuan 62O46O,China)

Abstract:This paperfocuses on the isse of high-power consumption of the dust blower in woodworking moulder but unsatisfactorydustremovalcapacity.Byanalyzing theexisting solutions to improve thedust removal capacityand selecting a popular four-sided moulderon the market as the research object,the flow field inside the suction hood is analyzedbyadng boundary conditions suchasoutlet flow velocityand moulder blade speed.The potential factors affecting the dust removal capacityand dust blower power consumption are identified.Based on this,a scheme to optimize the structure inside the suction hoodto improve dust removal capacity is proposed.The flow field,air flow path,dust removal capacity,anddust blower power consumption beforeand after the structural optimization are compared and analyzed to draw corresponding conclusions.This provides a new solution for reducing the power consumption of the dust blower and optimizing the dust removal capacity of the product.

Key words:dust removal capacity;flow field;dust blower;power consumption;suction hood; four-sided moulder

目前国内外都在大力发展木工高速四面刨,相比传统的普通四面刨,高速四面刨产生更多的刨花。(剩余4444字)