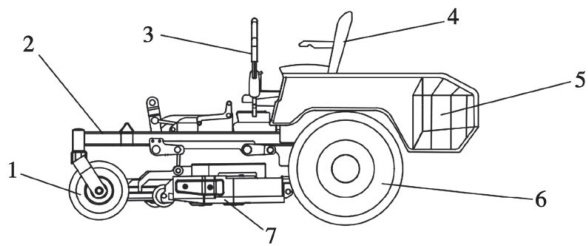

骑乘式双圆盘割草机切割装置的设计与仿真分析

打开文本图片集

关键词:切割装置;ANSYSWorkbench;模态分析;ADANS运动学仿真;接触力中图分类号:S731.2;S776.27+2 文献标识码:A 文章编号:2095-2953(2025)07-0031-07

Design and Simulation Analysis of the Cutting Device for Riding Double-Disc Mower

CHUFu-sen’,TIANFeng-nian',XU Guang-ming',WANGShuo 1 , CAO You-wei1 ,ZHANG Zhong-liang²

(1.ColegeofMechanicalandElectricalEngineering,NortheastForestryUniversity,Harbin,Heilongjiang150,China; 2.HarbinResearch InstituteofForestryMachinery,the StateForestryAdministration,Suihua Heilongjiang 152499,China)

Abstract:The cuting device is the core component of the riding-type dual-disk lawn mower,playing a crucial role in the qualityandreliabilityof itsoperation.This paper designs a riding-typedual-disk lawn mower that mets operationalrequirements basedonthe actual needs of modern lawns.Through static simulationanalysis of the mower blades using ANSYS Workbench,the study shows that the maximum stresson the blade is 63.34 MPa,which is much lower than the allwable stressof 35O MPa for 65 Mn,meting the operational requirementsand ensuring operationalsafety.Modalanalysisof the mowerbladesreveals thatthelimitrotational speedcoresponding tothefirst-order natural frequency is 7611.6r/min ,while the maximum working rotational speed of the blade is 3000r/min , far below the dangerous rotational speed range,thus preventing resonance.Kinematic simulation using ADAMS shows that the maximum contact force whenthe blade contacts the weeds is225ON,whichis much higher than the cutting shear force required,indicating that the cutting components can eficiently complete the mowing task under normal working conditions.The research results providea data foundation and new ideas for the optimized design of the cutting device in the riding-type dual-disk lawn mower.

Key words:cutting device;ANSYS workbench;modal analysis;ADAMS kinematic simulation;contact force

随着城市化进程的加速,城市绿地及其绿化草坪的养护管理在园林工程中愈发凸显其重要性[1]草坪被广泛应用于多个领域,包括园林建设、街道绿化、盐碱地改良、防风固沙以及坡地和堤岸的保护[2-5]。(剩余6742字)