实木板材铣削加工的表面质量影响及试验分析

打开文本图片集

中图分类号:S777 文献标识码:A 文章编号:2095-2953(2025)06-0023-08

Surface Quality Influences and Experimental Analysis of Solid Wood Board Milling

XUE Bo,LIU Wei-zheng,REN Chang-qin,WANG Xin (School of MechanicalandElectricalEngineering,NortheastForestry University,HarbinHeilongjiang15oo6,China)

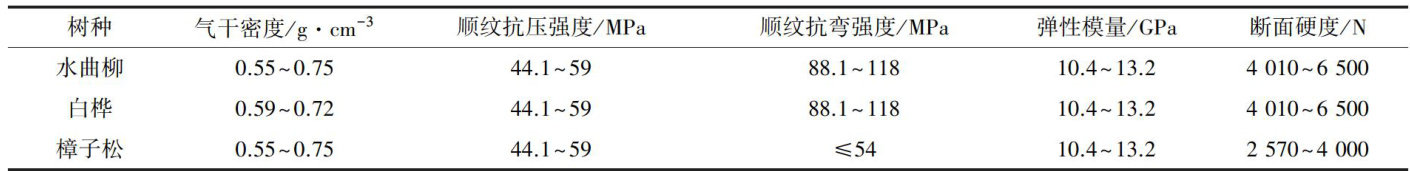

Abstract:This study investigates the milling of solid wood boards using a CNC woodworking machine,focusing on the effects ofdiffrent millng methods,cutting depths,spindle speeds andfeed rates on birch wood milling.The surface quality of boards after processng under various machining parameters is observed using a pointer probe and an ultra-depth-of-field 3D microscope.Additionally,birch,ash and pine woods are miled under the same machining parameters,and their surfacequality is analyzed using the same instruments to clarify the influence of wood species. The results indicate that for the same wood species,climb milling(conventional milling),smaler cuting depths, higher spindle speeds,and lower feed rates yield superior surface quality.When machining parameters are fixed, diffrences in wood species also result in distinct surfacequalities after milling.This experimental research provides insights for selecting machining parameters,methods,and material types,laying a foundation for future studies on enhancing the surface quality of solid wood boards through milling.

Key words: wood milling;surface quality;milling parameters;experimental analysis

实木板材在我们的生活中随处可见,实木板材的铣削加工是指使用刀具沿着特定的表面进行铣削,得到具有较高的表面加工质量的工艺过程,板材的表面加工质量主要包括板材的几何尺寸和表面形状的精度。(剩余8717字)