基于曲率的光固化打印自适应厚度切片算法

打开文本图片集

中图分类号:TH164 文献标识码:A 文章编号:2095-2953(2025)05-0078-07

An Adaptive Thickness Slicing Method for Photopolymerization Printing Based on Curvature

GAO Xiao-kuo1, ZHAO Wen² * , DAI Gui-xin², GUO Yan-ling²

(1.Colege of Computer and Control Engineering,NortheastForestry University,Harbin Heilongjiang 15O040,China; 2.Collgeof MechanicalandElectricalEngineering,NortheastForestryUniversity,HarbinHeilongjiang15o40,China)

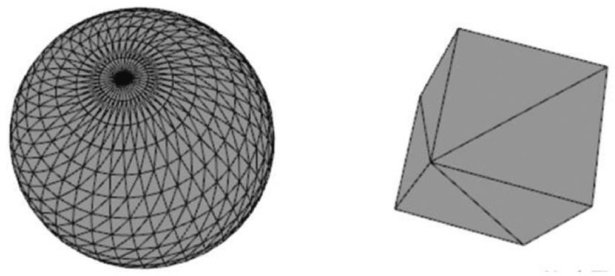

Abstract:Large-scale DLP stereolithography(SLA)3D printing technology,with its high resolutionand ability to handle complex geometries,is widelyused in industrial manufacturing.However,traditional fixed-layer-thickness slicing methods present two main issues: when the layer thickness is too large,step efects occur in complex regions, compromising surface quality;when the layer thickness is too small,the number of slices increases,leading to reduced printing eficiency.To address these isses,this paper proposes acurvature-based adaptive thickness slicing algorithm,which dynamicalyadjusts theslicing thickness byanalyzing thelocal geometric featuresof the model's surface.In high-curvature regions,the algorithm refines theslices to maintain detailed features;in low-curvature regions,it thickens the slices to reduce redundancy and improve eficiency,while ensuring overallsurface quality. Experimental results show that,although the algorithm cannot surpasstheoptimal forming efect achieved bythe minimumfixed layer thickness,itsignificantly reduces the number of slices and printing time while maintaining nearly optimal quality,thus demonstrating a considerable improvement in printing eficiency.

Key words:stereolithography (SLA)printing; large-scale; curvature;curvature gradient;adaptive thickness sli-cing

随着3D打印技术的快速发展,凭借高精度、高效率以及对复杂几何结构的优越成型能力,其已逐渐成为工程机械、模具制造等领域的重要技术工具[12]。(剩余8241字)