基于热力学数据对钛微合金钢TiN高温沉淀的统计分析计算

打开文本图片集

中图分类号:TG142.33 文献标志码:A 文章编号:1672-0105(2025)02-0064-04

Statistical Analysis and Calculation ofHigh-temperature Precipitation of TiN in Titanium Microalloy Steel Based on Thermodynamic Data

PENG Xiying', CUI Yan², XU Xianglai² (1.TangshanPolytechnicUniversity,Tangshan O63299,China;2.TangshanNormalUniversity,Tangshan06309,China)

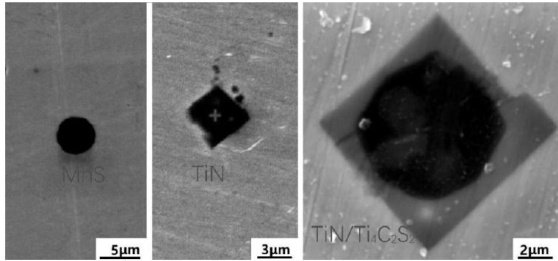

Abstract:Basedontheanalysis andcalculationof physicalchemistryphase and thermodynamicdata,the high-temperature precipitationbehavioroftitaniummicroaloyedsteelwasstudied.Itwasfoundthatthehigh-temperatureprecipitatesin Titanium-microalloyed steels predominantly consist of TiN and Ti4C2S2 phases.Liquid-phase precipitated TiN particles exhibit limited quantity and coarse dimensions,typically ranging from submicron-scale ( 100-1000nm )to micron-scale (>1μm) . In contrast,thesolid-phase precipitationofTiismoreabundant,withsizesrangingfrom100to0Onanometers.AdditionallyTiC particles havearelativelylowprecipitationtemperatureandsizesrangingfromafewtotensofnanometers.Furthermore,it was observedthatincreasing thetitanium(Ti)andnitrogen (N)content leadstoa higherproportionofcoarse liquid-phase TiN precipitation. However, when the Ti and N content is low, the formation of liquid-phase TiN can be avoided. The theoretical calculationsindicatethatwhentheNcontentisfixed,tereexistsaciticalvalueofTicontentBelowtiscriticalvalue,itanavoid thedetrmentaleffectofcoarseliquid-phaseTiNformationonductility.Controlling theTicontent withintherangeof0.1to 0.12wt% and the N content below or equal to 0.0035wt% can effectively suppress the liquid-phase precipitation of TiN while ensuring an adequateamountofTiCprecipitationforstrengtheningefects.Moreover,duringthehomogenizationprocesofthebilet,the coarsening rate of TiN is slow,and its influence on the particle size can be neglected.

Keywords: precipitation; TiN; liquid-phase precipitation; solid-phase precipitation

0引言

Ti微合金化钢中存在TiN、 Ti4C2S2 和TiC等大量沉淀物[1-2],其形成贯穿连铸到卷取各阶段[3-7: ① 连铸和冷却阶段TiN和 Ti4C2S2 的液析及固相析出;

② 精轧阶段TiC的形变诱导析出; ③ 层流冷却阶段TiC的相间析出; ④ 卷取缓冷阶段TiC在铁素体中的过饱和析出。(剩余4477字)