基于脉冲涡流检测系统的管道内检测机器人设计研究

打开文本图片集

中图分类号:TB9;TG115.28 文献标志码:A 文章编号:1674-5124(2025)07-0136-11

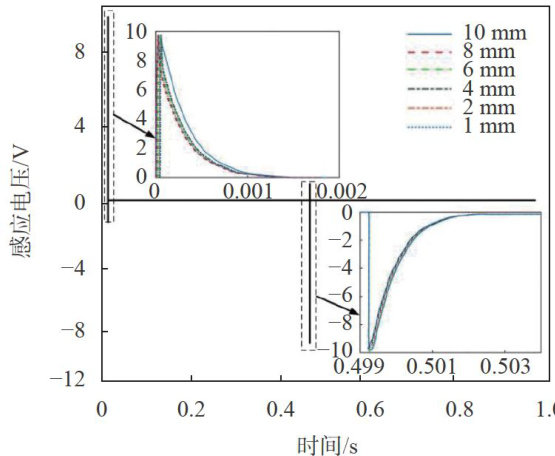

Abstract: Due to poor working conditions,there are often defects such as area corrosion and scaling in the atached tower pipelines in petrochemical plants,leading to pipeline failure and posing significant risks to the normal operation and production of the factory. Regular safety inspections are required inside the pipelines. Based on the damage mode and structural characteristics of the atached tower pipeline,this article designs a self-driving three-segment flexible pipeline internal inspection robot equipped with a multi-channel pulse eddy current detection system to address the pain points in manual detection. The robot has good motion centering and stable support performance. To explore the detection effect of pulse eddy currnt detection system in industrial pipelines,a finite element simulation model for pulse eddy current magnetic measurement of ferromagnetic pipelines wasestablished,and its feasibility was verified through thickness measurement experiments. Finally,combined with a fully integrated internal inspection robot prototype, a DN20o diameterelbow sample pipe was used as the experimental object to compare the robot inspection results with ultrasonic thickness measurement results.The results showed that the pipeline robot can achieve high sensitivity,full coverage,and non - destructive internal inspection of industrial pipeline wallthickness area corrosion defects, with thickness detection errors controlled within ±7% , and can quickly screen suspicious corrosion locations. It can be further promoted in relevant industry equipment testing.

Keywords: attached tower pipeline; pipeline corrosion detection; pulse eddy current testing of ferromagnetic pipelines; self driving wall pressure internal inspection robot

0 引言

在石化企业中,管线网络长期服役于相对恶劣的环境,部分带有保温的管线(如附塔管线)常由于局部保温层的破损和支撑不连续等,导致雨水进入后不易排出,形成了管道保温层下腐蚀(CUI),管道泄漏事件时有发生[1。(剩余11668字)