金合金导电环刷丝结构与转速对配对副材料摩擦性能的影响

打开文本图片集

摘 要:导电滑环是实现两个相对旋转机构之间电流、信号传输的装置。本实验探究刷丝结构与转速对配对副材料的摩擦性能影响。结果表明:常温常压下,配对副的接触面积越大,摩擦系数越大,接触电阻越小;反之,摩擦系数越小,接触电阻越大;单丝结构配对副材料的摩擦系数最小且稳定。

关键词:导电滑环;刷丝结构;转速;摩擦系数;接触电阻

中图分类号:TM934.14 文献标志码:A 文章编号:2095-2945(2022)01-0054-03

Abstract: The conductive slip ring is a device that realizes the transmission of current and signal between two relative rotating mechanisms. In this experiment, the effects of brush wire structure and rotational speed on the friction properties of pair materials were investigated. The results show that under normal temperature and pressure, the larger the contact area of the pair is, the larger the friction coefficient is and the smaller the contact resistance is; on the contrary, the smaller the friction coefficient is, the greater the contact resistance is; in this case, the friction coefficient of monofilament structure is the smallest and stable.

Keywords: conductive slip ring; brush wire structure; rotational speed; friction coefficient; contact resistance

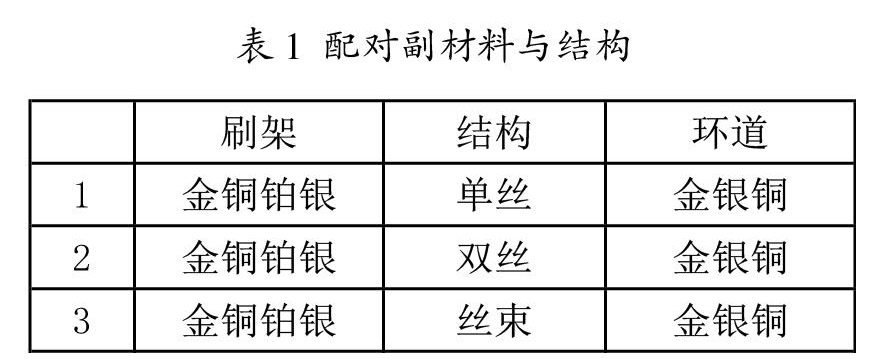

导电环是两个相对旋转设备之间用来传递电流、信号的关键零部件,主要是依靠电刷架和滑环组成的配对副之间进行滑动接触,进而在两个旋转体之间传递电流和信号[1-2],是整个设备中最容易失效的单体零部件之一。(剩余3126字)