某型气动阀橡胶膜片破裂故障仿真

打开文本图片集

中图分类号:V254.1;TH145.41 文献标志码:B

Simulation on rupture failure of rubber diaphragm in the pneumatic valve

CHEN Shaoyan,LIU Zhonghua,HE Wang,WANG Bing,FANG Ling, XIA Yan

(Hefei Jianghang Aircraft Equipment Co.,Ltd.,AVIC,Hefei23OO51,China)

Abstract:As to the rupture failure of rubber diaphragm in the pneumatic valve,the influence of key structural parameters, such as the thickness and fillet radius of the diaphragm’s corrugated area,on the diaphragm’s fatigue life is investigated.Based on the rubber material’s constitutive model and fatigue crack growth model,a three-dimensional finite element model of rubber diaphragm isestablished to simulate the stress and deformation of rubber diaphragms with different structural parameters under loading conditions,and to predict the fatigue life of the rubber diaphragms.Based on the simulation results,optimization measure for the rubber diaphragm structure is formulated and experimentally validated through fatigue life testing. The results show that the failure locations in pre-optimization diaphragm is closely aligned with both field observation and simulation prediction,therebyvalidating the analytical methodology. The optimized diaphragm structure exhibited markedly extended fatigue life, conclusively demonstrating the efficacy of the optimization measure.

Key words: pneumatic valve;rubber diaphragm;rupture; finite element; fatigue life;optimization

0引言

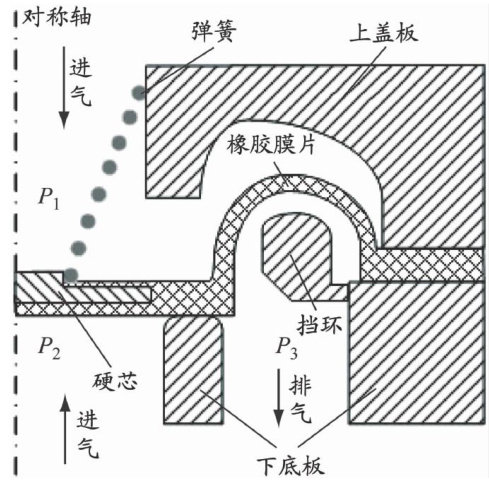

某型气动阀是某航空氧气系统的核心部件,承担着控制气体流向的关键功能,其依靠压力信号控制促使橡胶膜片在气压差下进行开闭运动,从而实现气源的切断或接通[]。(剩余8259字)