新型抑制剂AMT对Cu/Ru/TEOS去除速率选择性的影响

打开文本图片集

关键词:Ru;化学机械抛光(CMP);AMT;去除速率选择比;碟形坑;蚀坑

中图分类号:TN305.2;TQ421.4

文献标识码:A

DOI:10.14106/j.cnki.1001-2028.2025.1520

引用格式:尤羽菲, 马慧萍, 周建伟, 等. 新型抑制剂AMT对Cu/Ru/TEOS去除速率选择性的影响 [J]. 电子元件与材料, 2025, 44(3): 331-337.

Reference format: YOU Yufei, MA Huiping, ZHOU Jianwei, et al. Effect of novel inhibitor AMT on the selectivity of Cu/Ru/TEOS removal rate [J]. Electronic Components and Materials, 2025, 44(3): 331-337.

Effect of novel inhibitor AMT on the selectivity of Cu/Ru/TEOS

removal rate

YOU Yufei 1,2, MA Huiping 1,2, ZHOU Jianwei 1,2, LUO Chong 1,2

(1. School of Electronic Information Engineering, Hebei University of Technology, Tianjin 300130, China; 2. Tianjin

Key Laboratory of Electronic Materials and Devices, Tianjin 300130, China)

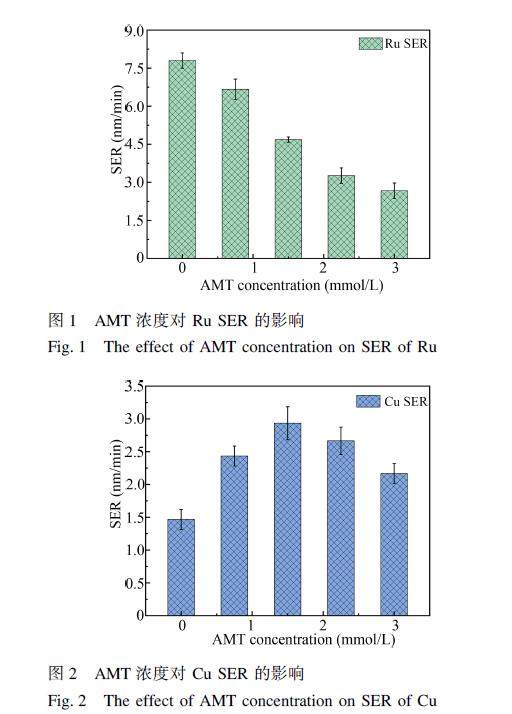

Abstract: For Ru barrier layer chemical mechanical polishing, the main challenges are low Ru removal rate and difficulty in achieving a good Cu/Ru/TEOS removal rate selectivity ratio. In order to solve the above problems, a new inhibitor AMT was introduced based on the KIO 4-K 2S 2O 8dual oxidant system to enhance the Ru removal rate and surface quality and improve the Cu/Ru/TEOS selectivity ratio. The polishing experiment confirmed that the removal rate selectivity of Cu/Ru/TEOS could be adjusted by introducing AMT into the KIO4-K2S2O8 system. The surface quality of Ru before and after the introduction of AMT was compared using AFM testing, and the result showed that the surface roughness of Cu/Ru was improved by the introduction of AMT in the KIO4-K2S2O8 system. Dishing pit and etching pit testing confirmed that the introduction of AMT had a corrective effect on the dishing pits and etching pits, and the role of AMT in the CMP process of the Ru barrier layer was revealed. The final Cu/Ru/TEOS rate selectivity ratio reaches 1∶1.3∶1.7, and at this time, the correction effect of dishing pits and etching pits are good, with correction values of 54.4 nm and 49.4 nm, respectively.

Keywords: Ru; chemical mechanical polishing (CMP); AMT; removal rate selectivity ratio; dishing pit; etching pit

随着集成电路(IC)特征尺寸的进一步缩小,传统铜(Cu)互连阻挡层钽(Ta)和氮化钽(TaN)难以满足微电子技术的要求 [1-3]。(剩余10199字)