打叶复烤成品长梗率的影响因素分析

打开文本图片集

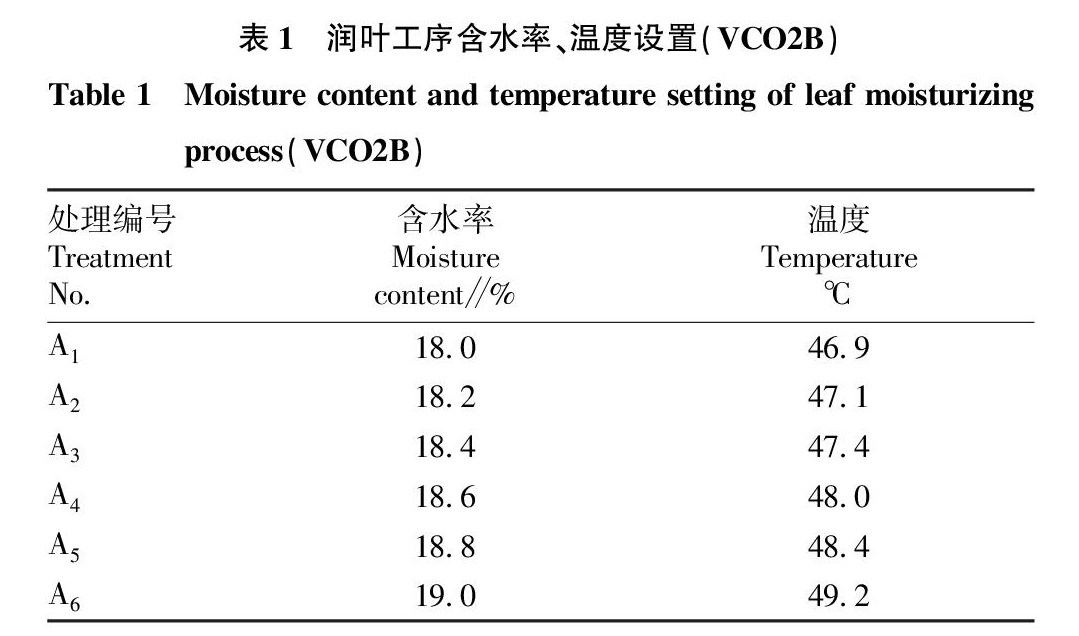

摘要 通过对润叶、打叶、回梗系统参数调整、新型异形筛应用进行研究,结合叶片结构、烟梗结构检测结果,得出一套提升打叶复烤成品长梗率的关键参数模型,有效提高烟叶来料与设备工艺参数的匹配性,有利于提高打叶风分后的叶片和烟梗质量,提升成品长梗率,为复烤设备的调试和操作提供理论依据。

关键词 打叶复烤;回梗系统;长梗率;打叶风分参数;新型异形筛

中图分类号 TS 44 文献标识码 A 文章编号 0517-6611(2022)09-0175-04

doi:10.3969/j.issn.0517-6611.2022.09.043

开放科学(资源服务)标识码(OSID):

Influencing Factors Analysis of the Long-stem Rate of Threshing and Redrying Products

BAI Yin-liang, WANG Xiang-fei, LEI Xiang et al

(Hongta Tobacco(Group) Co.,Ltd., Yuxi, Yunnan 653100)

Abstract The system parameter adjustment of leaf moisturizing, threshing, back stem system, and the application of new special-shaped sieve were studied and optimized. Combined with the detection results of leaf structure and tobacco stem structure, a set of key parameter model for the improvement of long-stem rate of threshing and redrying products was drawn. The matching degree of incoming tobacco materials and equipment process parameters was effectively improved. It was beneficial to improve the quality of leaves and stems after threshing and air separation and improve the long-stem rate, which could provide theoretical basis for the debugging and operation of redrying equipment.

Key words Threshing and redrying;Back-stem system;Long-stem rate;Threshing and air separation parameters;New special-shaped sieve

随着卷烟新工艺、新技术的不断应用,在烟丝中掺配梗丝和薄片丝的比例不断增大,使企业对烟梗的使用量激增。(剩余4108字)