计算机模拟在模具热处理工艺优化中的关键技术研究

打开文本图片集

Key technologies of computer simulation in optimizing mold heat treatment processes

MA Leijuan

(Henan Polytechnic Institute,Nanyang 473ooo,Henan,China)

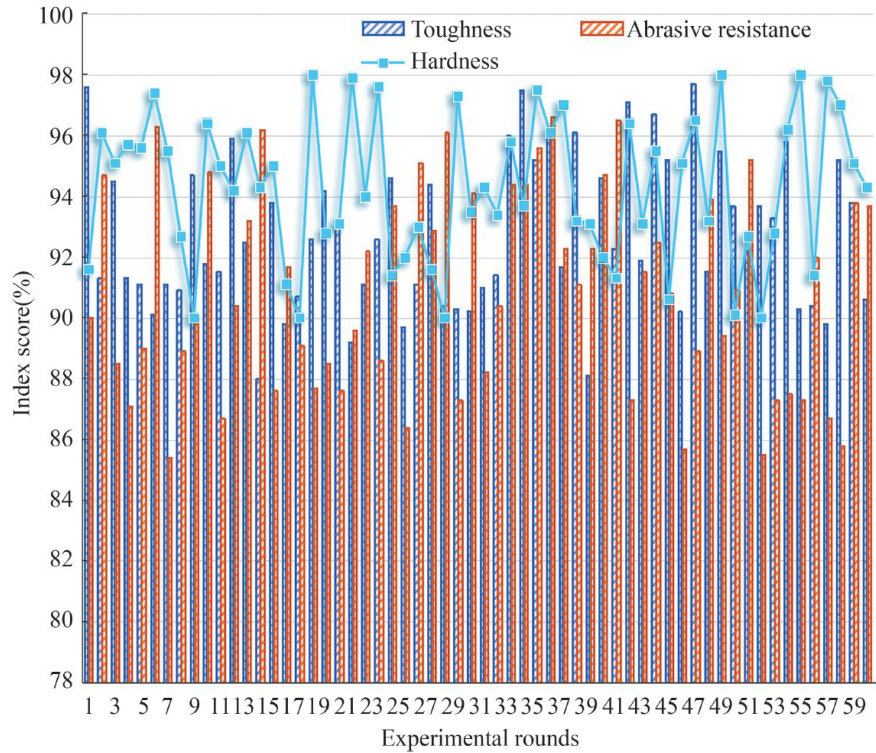

Abstract: This studyinvestigates the application of genetic algorithm technology in optimizing mold heat treatment process,aiming to improve the mechanical properties and service life of molds. By incorporating computer simulation technology, the key role of genetic algorithm in determining the optimal heat treatment parameters is analyzed. Firstly, the heat conduction model and phase change model are constructed to accurately describe the temperature distribution and microstructure evolution of the die during heat treatment. Then, a multiobjective optimization strategy based on genetic algorithm is proposed, which can efficiently identify the optimal heat treatmentparametercombinationsunder multi-constraints. Through numerical solution of the heat conduction equation and the phase transition dynamic model, the physical behavior of the mold during heat treatment is simulated,and the process parameters are optimized by usinggenetic algorithm. The numerical results show that the heat treatment process optimized by genetic algorithm improves the hardness, toughness and wear resistance of the die. Sensitivity analysis and statistical verification further confirm the stability and reliability of the optimization result. The research results provide theoretical foundations and practical references for the optimization of mold heat treatment process, while demonstrating the potential of genetic algorithm in solving complex engineering optimization problems.

Key words: heat treatment of mold; computer simulation; heat conduction model; phase change model; genetic algorithm

0 引言

模具是工业制造中的核心工艺装备[1]。(剩余5918字)