基于五轴加工技术的汽车节气门压铸件加工方案设计与实践

打开文本图片集

Design and practice of automotive throttle valve die casting part processing based on five-axis machining technology

JIAO Zhenghui',2,WANG Shuai³, GAO Dongdong³, XIE Mingming², JIA Wangbin4,WU Kai1,2

(1. Shaanxi Polytechnic Institute,Xianyang 712Ooo, Shaanxi, China; 2. Precision Processing Technology R& D Center of Shaanxi Polytechnic Institute, Xianyang 71200o, Shaanxi, China; . Xi'an Jingdiao Precision Mechanical Engineering Co. Ltd., Xi'an 710ooo, Shaanxi, China; 4.Xi'an Aerospace Power Machinery Co. Ltd.,Xi'an 71Oooo, Shaanxi, China)

Abstract:This article focuses on the key technical challenges faced in the machining process of automotive throttle body castings, such as high precision requirements,complex machining features,and difficulties in clamping and alignment of raw materials. It proposes a five-axis combination processing solution. The solution systematically covers key aspects such as the selection of high-precision machining centers, the optimization of special cutting tools,the design and precision manufacturing of customized fixtures, and the comprehensive upgrade of inspection processes. Through practical application and rigorous verification, the solution has significantly improved the machining accuracy and yield rate (over 95% )of throttlebody castings. The successful implementation of this case not only provides a highly efcient and feasible solution for the machining of automotive throttle body castings, but also provides new ideas and references for technological innovation and process optimization in related fields.

Keywords:five-axis;die-casting;machine tool;throttle

0 引言

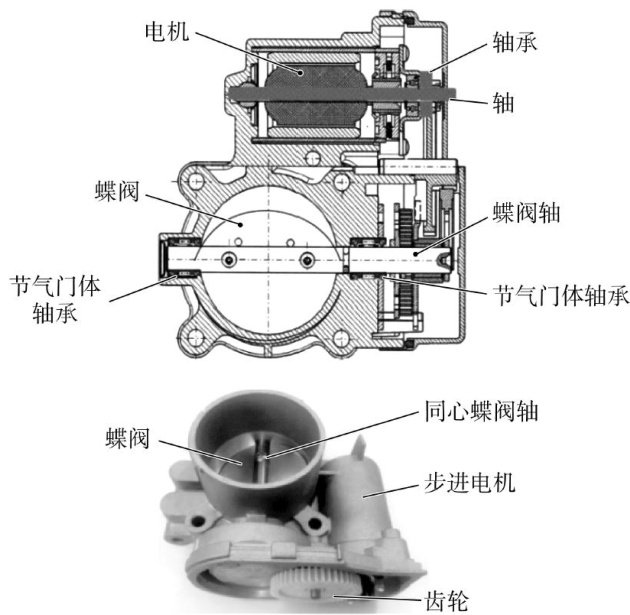

汽车节气门是控制空气进人发动机的一道重要可控阀门,它上接空气滤清器,下接发动机缸体,被称为是汽车发动机的“咽喉"(图1)。(剩余6438字)