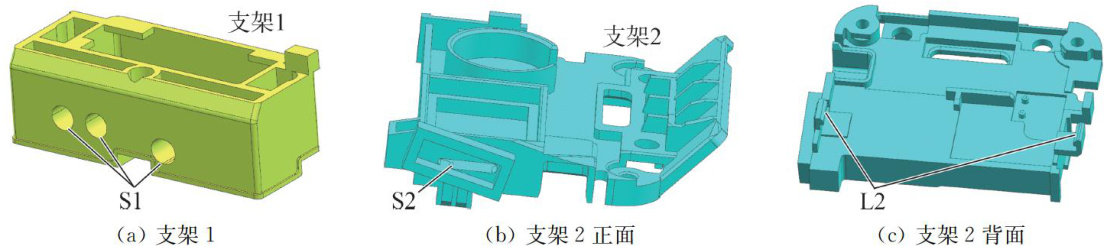

两支架混合四腔的注塑模具设计

打开文本图片集

Injection mold design of two-support combined four-cavity

SONG Jinya

(Shanghai Technical Institute of Electronics and Information, Shanghai 2O1411, China)

Abstract: Based on the analysis of the structural characteristics of two supports with large structural differences,the preliminary design of four-cavity mold was completed by mixing them in the same mold according to the actual needs. The simulation of flow channel balance was carried out by using Moldflow. The size of branch runner and gate was optimized. The cooling water channel was circulating. The analysis results of ∘cooling+filling+holding+ warping’ show that the temperature difference between the inlet and outlet of the cooling medium does not exceed 0.33K ,and the filling effect is relatively balanced.The maximum total warping deformation of the two supports is 0.1385mm and 0.1478mm ,respectively, which meets the requirements. Three sets of sliders and two sets of lifters were used to realize side core parting and stripping. Multiple inserts in the cavity and core could reduce the cost and facilitate mold repair. Finally,a set of combined four-cavity two-plate injection mold which can be used in actual production was obtained. It can provide some reference for the injection mold design of combined multi-cavity and unbalanced runner with different models.

Key words: combined four-cavity; injection mold; mold design; mold flow analysis;warpagedeformation

0 引言

注塑模具由于制作成本较高,如果前期设计过程中存在问题,轻则导致频繁修模,重则导致整套模具报废,会带来较大的损失,而利用模流分析软件Moldflow在模具设计初期进行仿真分析,可有效降低设计失误,提升设计效果,降低成本,缩短项目周期[1-4]。(剩余7811字)