基于机器学习的发动机缸体锥齿轮塑性成型工艺研究

打开文本图片集

Research on plastic forming process of engine cylinder cone gear based on machine learning

WANG Limeng,YANG Quan

(Guangxi Vocational & Technical Institute of Industry, Nanning 53oo01, Guangxi, China)

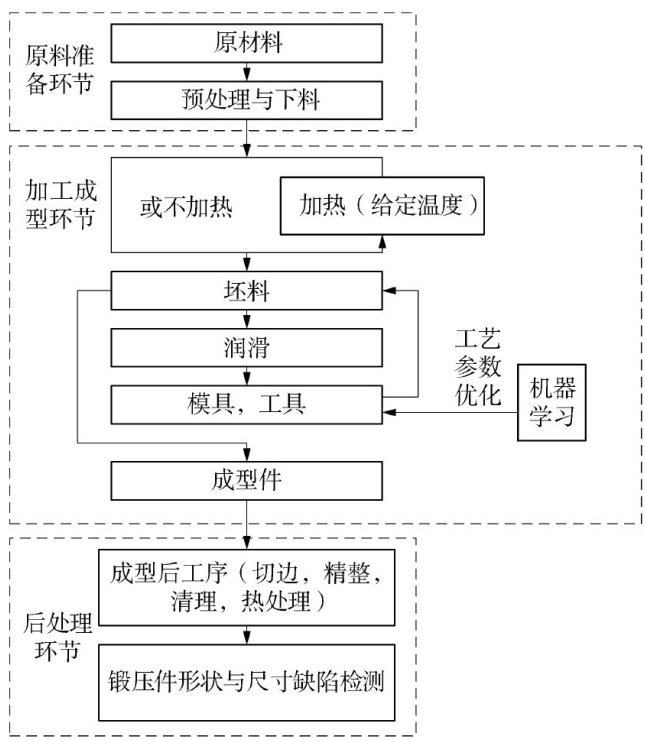

Abstract: To improve the quality of plastic forming production of engine cylinder bevel gears, a machine learning based plastic forming process is studied. Design the plastic forming process of the engine cylinder body bevel gear to ensure that each step meets the material characteristics and product requirements. Utilize the principal component analysis method in machine learning to obtain the main process parameters,and prepare plastic formed parts based on the obtained process parameters. By simulating the actual forming process,the possible problems can be predicted and the process parameters can be adjusted in advance. Using deep learning methods to detect defects in plastic formed parts to ensure product quality meets standards. The experimental results show that the plastic formed parts prepared by extracting process parameters using principal component analysis method have hardness, tensile strength,yield strength,and elongation at break that are close to or slightly higher than the design values;The mechanical performance test results are basically consistent with the expected situation during the initial design,which can significantly improve the efficiency and success rate of plastic forming; Capable of accurately detecting various defects in plastic formed parts,ensuring the quality of plastic formed parts.

Key words: machine learning; plastic forming; raw material; principal component analysis;process parameters;defect detection

0 引言

在材料加工领域,塑性成型工艺作为锻造、轧制等技术的核心,对于汽车、航空等高端制造业的发展至关重要[1-2]。(剩余8149字)