模具全生命周期管理在铝型材智能制造中的应用研究

打开文本图片集

Theapplication of the lifetimemanagement ofthe extrusion die during the intelligent manufacture of al alloy profiles

LU Ying

(Inner Mongolia Vocational and Technological College of Communication, Chifeng O240O5,Inner Mongolia,China)

Abstract: The molds as the core component in the processing of aluminum alloy profiles, their storage logistics and fullifecycle management are of great significance in improving the yield rate and enhancing product quality of aluminum profiles. With the circumstance of advocating for digital intelligent manufacturing transformation domestically, this paper realizes the full lifecycle management of molds through the system development and integration of mold storage design, intelligent transportation, mold end-face automatic identification technology, and the analysis and statistics of mold output and product quality. This addresses the inefficiencies,low automation levels,and high labor intensity associated with the existing QR code identification of molds. By automatically analyzing the correlation between mold status and product quality, an analysis and prediction model for mold quality is formed. This effectively improves the yield rate of products, shortens the production cycle, and assists enterprises in reducing costs and increasing eficiency,while providing critical data support for the further optimization of mold structures.

Key words: mold; aluminum profile; extrusion; lifecycle management;intelligent manufacturing

0 引言

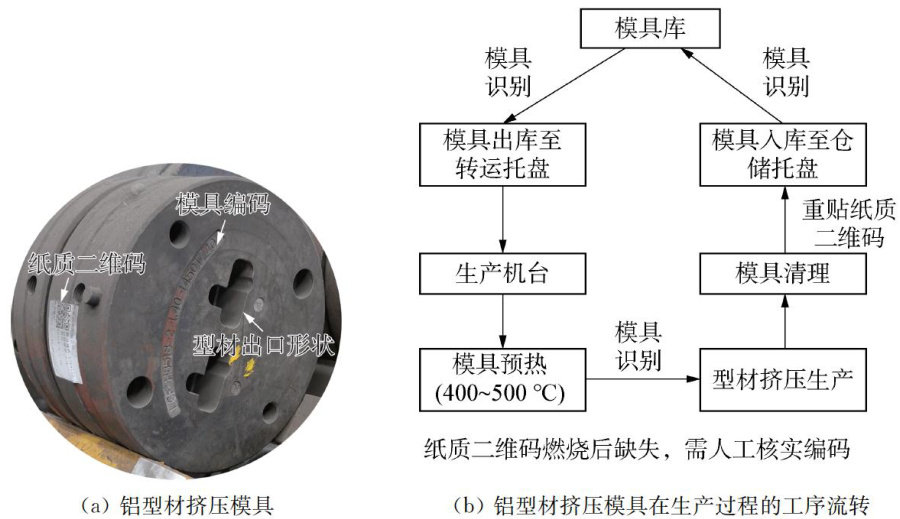

铝合金因具有质量轻、强度高、耐腐蚀、易成型等优势,在满足服役性能的条件下,以铝代钢可减重 20%~30% ,因此铝合金的应用已成为航空航天、交通、新能源等领域轻量化的主流[1-2]。(剩余8578字)