汽车用220MPa级超低碳烘烤硬化钢耐时效性能研究

打开文本图片集

中图分类号:TG142 文献标志码:B DOI:10.19710/J.cnki.1003-8817.20250088

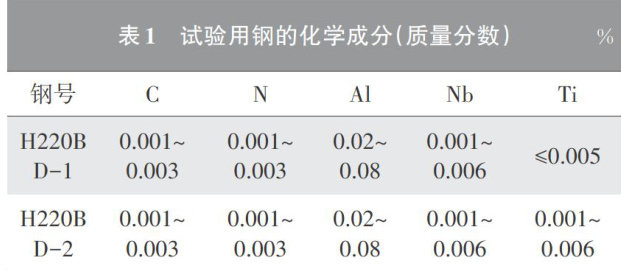

Abstract:Taking 22O MPa grade ultra-low carbon bake-hardening stels as the research object,this paper compares and aralyzes test steel with Nb single-addition (H220BD-1) and Nb+Ti dual-addition (H22OBD-2) systems. Through solid solutioncarbon calculationsand internal friction methoddetermination,the paper explores the influence of solidsolution carbon onaging behavior underdiferent compositionsystems,andcombines with microstructuregriain sizecharacterization to elucidate the correlation mechanism between grain dimensions and Bake-Hardening (BH) value with aging resistance.Results demonstrate that Ti adition significantly reduces solid solution carbon content, efectivelysuppressing dynamiccarbon segregation during aging.Thedual-addition system achieves grainrefinement, enhancing strength via Hall-Petch effect while improving aging stability.

Keywords:Bake-hardeningsteels,Solid solutioncarbon,Agingresistance,Grainrefinement

1前言

超低碳烘烤硬化钢板(UCL-BH)是车身覆盖件的理想材料,因具有优异的冲压成形性能、良好的塑性、抗凹陷性能及抗冲击性能等,可以很好地解决汽车面板成形性能与抗凹陷性能间的矛盾,其是在超低碳IF钢的成分基础上通过加入Ti、Nb、V等稳定化元素,使钢中的绝大部分C、N原子被固定成碳氮化物,以获得较好的深冲性能[1-4],后经退火工艺使得基体内残留一定数量的固溶C原子,冲压钢板在经过烤漆处理后,获得性能的提升,从而提高了汽车的抗凹陷性能。(剩余5249字)