低成本前围板冲压工艺开发与验证

打开文本图片集

中图分类号:U466 文献标志码:B DOI:10.19710/J.cnki.1003-8817.20250040

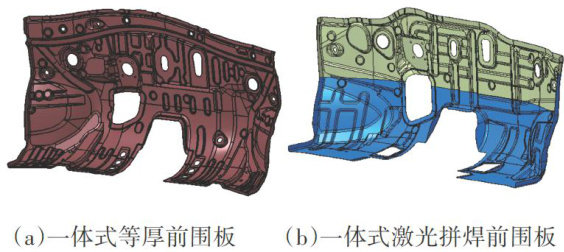

Abstract:Inorder torealizethelightweightofautobody,the traditional one-pieceBIWdashboardpanel is designed intotwoparts (theupperone andthelowerone)with differentthickness.According to the typical featuresof the front dashboard panel,namely thearch shape of theevacuation area of the wheel cover,this paper proposes shallow drawing plusreshaping tosimplify stamping processand greatly improve materialutilization rate.Inorder to address theisuesofcorrugationof dashboardupperpanel,insufficient stiffnessof singlepartandpoorwelding of evacuation area of the wheel cover,the paper verifies the feasibility of shallow drawing plus reshaping through stamping CAEanalysis,stamping physical production and welding quality verification.The cost saving advantage of split-type front dashboardpanel isconfirmed bythe cost accounting of the whole processchain (stamping,welding, coating).Finally the low-cost front dashboard panel is put into mass production withshallow drawing plus reshaping process.

Keywords:IW,ashboardpanel,Stamping,Materialutilizationrate,Formingsimlatic

1前言

汽车白车身成本是影响汽车成本的重要指标,为降低整车成本,研究在满足各项整车性能指标条件下的低成本白车身结构和工艺十分必要[-3]。(剩余5951字)