基于Autoform的拉延筋参数正交试验分析

打开文本图片集

中图分类号:U466 文献标志码:B DOI:10.19710/J.cnki.1003-8817.20250054

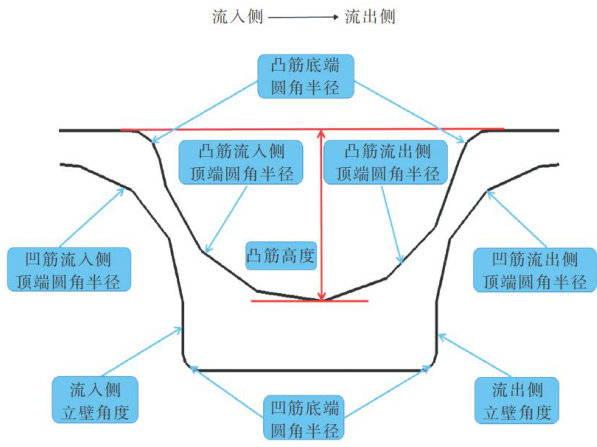

Abstract:To optimize drawbead parameters in stamping processes,a simulation model is established by using Autoform,withtheresistancecoeficientastheevaluationcriterion.Orthogonal testingandvarianceanalysisare employedtoinvestigate theinfluencelawsof9parametersondrawbeadresistance.Theresultsreveal that parameters such as thetop filet radiuson theinflowsideof theconcave drawbeadand the height of theconvex drawbead significantlyinfluencedrawbeadresistance,whilethewallangleandbottomcornerradius haveminimal impact.In engirering,regulating the keyparameters canreduce defects suchaswrinklingand cracking,thereby improving mold debugging efficiency and lowering production costs.

Keywords:Autoform,Drawbeadparameters,Orthogonalexperimental,Resistancecoefficient,Toillet RadiusontheInflowSideof theConcave Drawbead

1前言

以控制板料的流动状态[2。(剩余5590字)