定制家具板件开料顺序优化研究

打开文本图片集

中图分类号:S777 文献标识码:A 文章编号:2095-2953(2025)09-0087-07

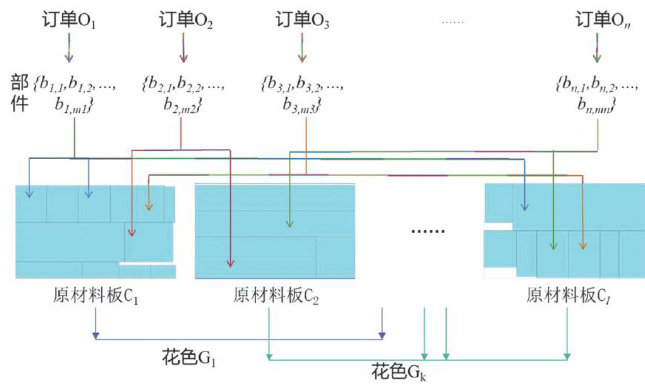

Abstract:The aim of this study is to address the issues of long order completion time,high caching requirements for subsequent processes,and high management complexity in the custom furniture cutting process due to the random order of raw material panels being put online.Propose a hybrid optimization strategy:firstly,use greedy algorithm to groupthe boards into diferent colors(ensuring continuityof the same color),and sort them between and within groups based on the coverage rate of unfinished orders and the density of board orders within each group; Subsequently,thegeneticalgorithmpopulation is initialized basedonthis solution,with thegoal of minimizing the weightedaverage processing distance and average storage capacity.Global optimization is carriedout through tournament selection,sequential crosover,and swappng mutation operations.Simulation experiments based on actual production parameters show thatcompared totherandomonline strategy,the hybrid algorithm significantlyoptimizes keyindicators. For example,in 3O order scenarios, the average processing distance decreases by 15.2% ,and the maximum storage capacity decreases by 21.7% . Moreover, it outperforms the single greedy algorithm in five indicators :average/maximum processing distance,average/maximum storage capacity,and the correlation between storage capacityand distance, especiallin highordervolumes.This algorithm efectively shortens theorder completion time,reduces sorting and caching requirements,and provides a practical method for optimizing customized furniture production lines.

Key words:cutting sequence;board buffering capacity;cutting distance;complete set of time;order aggregation

近年来由于存量房旧改需求持续释放,消费者个性化定制家具的需求持续增加,这对定制家具企业生产灵活性与效率的平衡提出了挑战[1]。(剩余9558字)