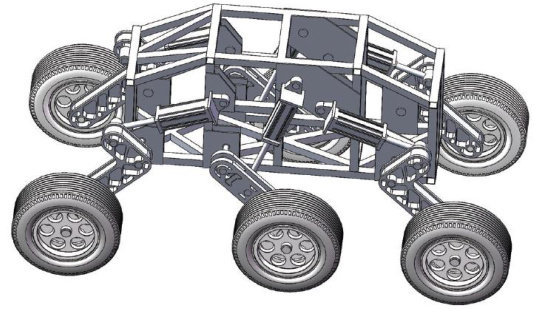

林业三轴无人车摆臂结构多目标优化设计

打开文本图片集

中图分类号:S776 文献标识码:A 文章编号:2095-2953(2025)09-0076-11

Abstract:This study focuses on the multi-objective optimization of the swing arm structure for a forestry tri- axle unmanned vehicle,aiming to achieve lightweight design while ensuring mechanical performance.Finite element models of the front/rear and middle axle swing arms were established using Hypermesh to evaluate their initial static strength and dynamic characteristics,with stress concentration areas identifiedasoptimization targets.Four design variables were selected for each of the two swing arm types. A sample space was constructed using the optimal Latin hypercube method,andsensitivity analysis was conducted toquantify thecontributionof each variable tothe response indicators.A third-order response surface methodology was employed to develop surrogate models between the input parameters and output responses(mass,maximum deformation,and maximum stress).A multi-objective particle swarm optimization(MPSO)algorithm was then used for collaborative optimization.The results showed thatthe mass of the front/rear axle swing arms was reduced by 3.58kg (a reduction rate of 11.4% ),and the mass of the middle axle swing arm was reduced by 8.78kg (a reduction rate of 22.3% ). The static strength,stiffness,and dynamic performance ofboth types of swing arms met the design requirements.This method,integrating finiteelement analysis andoptimization algorithms through the Isight platform,achieves abalancebetween lightweight designand engineering applicability,providing areferable technical approach for the multi-objective optimizationof complex mechanical structures.

Key Words:lightweight;response surface model; multi-objective optimization;multi-objective particle swarm optimization

现有林业车辆普遍依赖高能耗、高污染的柴油动力系统,其碳排放与噪声污染对林区生态环境造成显著压力。(剩余8440字)