基于振动-声音信号综合异常指标判断木材劈裂状态的检测研究

打开文本图片集

中图分类号:S784 文献标识码:A 文章编号:2095-2953(2025)09-0052-08

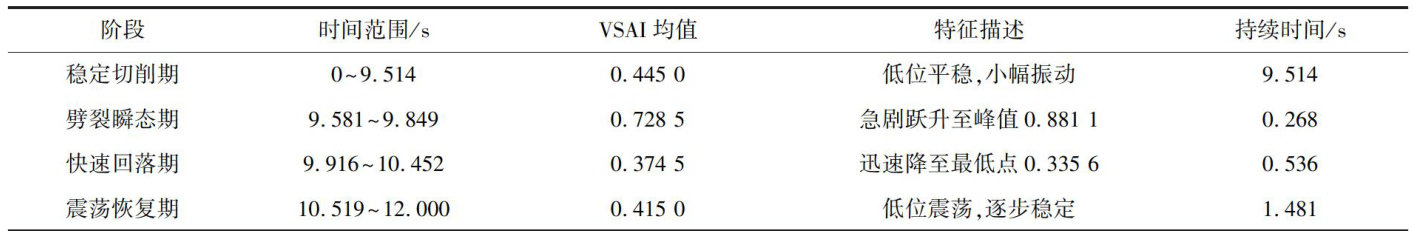

Abstract:Toaddress thechallengeof real-time monitoring of abnormal conditions in wood window frame miling processes,an inteligent detection method based on the Vibration-Sound Anomaly Index(VSAI) is proposed.Taking wood window frame miling equipment as the research object,a dynamic weight optimization-based feature fusion strategy is designed throughsynchronous acquisition of vibrationand acoustic signals.A comprehensivedetection system is established,integrating signal preprocessing,feature extraction,dynamic weightadjustment,andthreshold discrimination.Moving average filtering algorithms are employed to enhance signal quality,improving the signal-to一 noise ratio (SNR)of vibration and acoustic signals by 5.8dB and 6.4 dB,respectively. The VSAI index enables precise identification of abnormal processing conditions through adaptive adjustment of weight coefficients (w1,w2 , w3 )for vibration intensity,acousticanomaly,and correlation indicators.Experimental results demonstrate that the mean VSAI values differ by 17.3% between normal and abnormal operating conditions. Compared to fixed-weight schemes,the dynamic weight strategy improves detection accuracy from 91. 6% to 95.3% ,increases the F1 score from 0.912 to O.948,and reduces average response time to 0.2O seconds. The system can isue warnings 0.2 seconds before splitting occurs,providing sufficient time for procssadjustment. The method successullyidentifies four typical stages of processng anomaly evolution, where the 93.9% surge in VSAI during the transient splitting phase provides a reliable criterion for early warning.In practical production applications,this system efectively reduces wood processing defect rates,demonstrating significant engineering application value.

Key words:vibration audio compositeanomaly index(VSAI);dynamic weight optimization;wood spliting detectior

木窗铣削加工具有其特殊性,木材的各向异性会导致切削过程呈现非线性特征[1-3],不同材质的木材会产生不同的音频特征,且刀具磨损状态会在振动和音频信号中留下特征信息[4]。(剩余9438字)