惯性摩擦焊静压支承主轴间隙油膜瞬态流场研究

打开文本图片集

中图分类号:TH133.36 文献标识码:A 文章编号:2095-2953(2025)08-0015-05

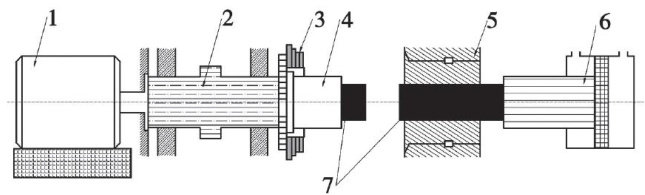

Abstract:Forthe high-quality manufacturing ofaero-engine disk and shaft components,the innovative structure of closed hydrostatic bearing was adopted in the spindle axial bearing system of the inertia friction welding machine.A mathematical model forthe attenuation ofthespindlerotationspeedof the inertia frictionwelding machine under the action of axial upseting force was established.Three-dimensional models and boundary conditions of clearance oil films in the hydrostatic bearing were established and determined.Utilizing CFD(Computational Fluid Dynamics), dynamic mesh technologyand Fluentsoftware,transient flow field of the hydrostatic bearing was studied during the working process,thatis,the flowvelocity distributionof clearanceoil films was discussed,when the inertia friction welding equipment was subjected to the upseting force.The results indicated that when the flow velocityon carrier side was innon-equilibrium state,the flow velocityoncarrierside increased firstand then tended to be stable with thereductionofthe thicknessofoilfilms.Theflowvelocityof thecariersideoilfilm increasedrapidlyand then increased slowly with the reduction of the oil film gapthickness,reaching the highest when the rotation stopped.In he non-equilibrium state,theflowvelocityof theback pressure side oil film decreased with the increase in the oilfilm gap thickness,and the flow velocity was relatively stable at the final position.

Key words:transient flow field;closed hydrostatic bearing;spindle system;inertia friction welding equipment; aero engine

国内外研究现状

NIE 等[1]建立了FGH96高温合金的动态再结晶动力学模型,模拟研究了惯性摩擦焊接过程的显微组织演变,得到了平均晶粒尺寸和动态再结晶分布,并得到实验验证。(剩余7138字)