基于RCM的“动态维修模式”研究与实践

打开文本图片集

中图分类号:U279 文献标志码:B doi:10.20214/j.cnki.zhgdjt.2025.04.017

Research and Practice of a “Dynamic Maintenance Pattern” Based on RCM

CHEN Qiang,GENG Tao, JIN Xiaojiao, ZHAO Jiefang,LIU Yan, ZHANG Chunyang(CRRCYongji Electric Co.,Ltd.,YunchengO44502,China)

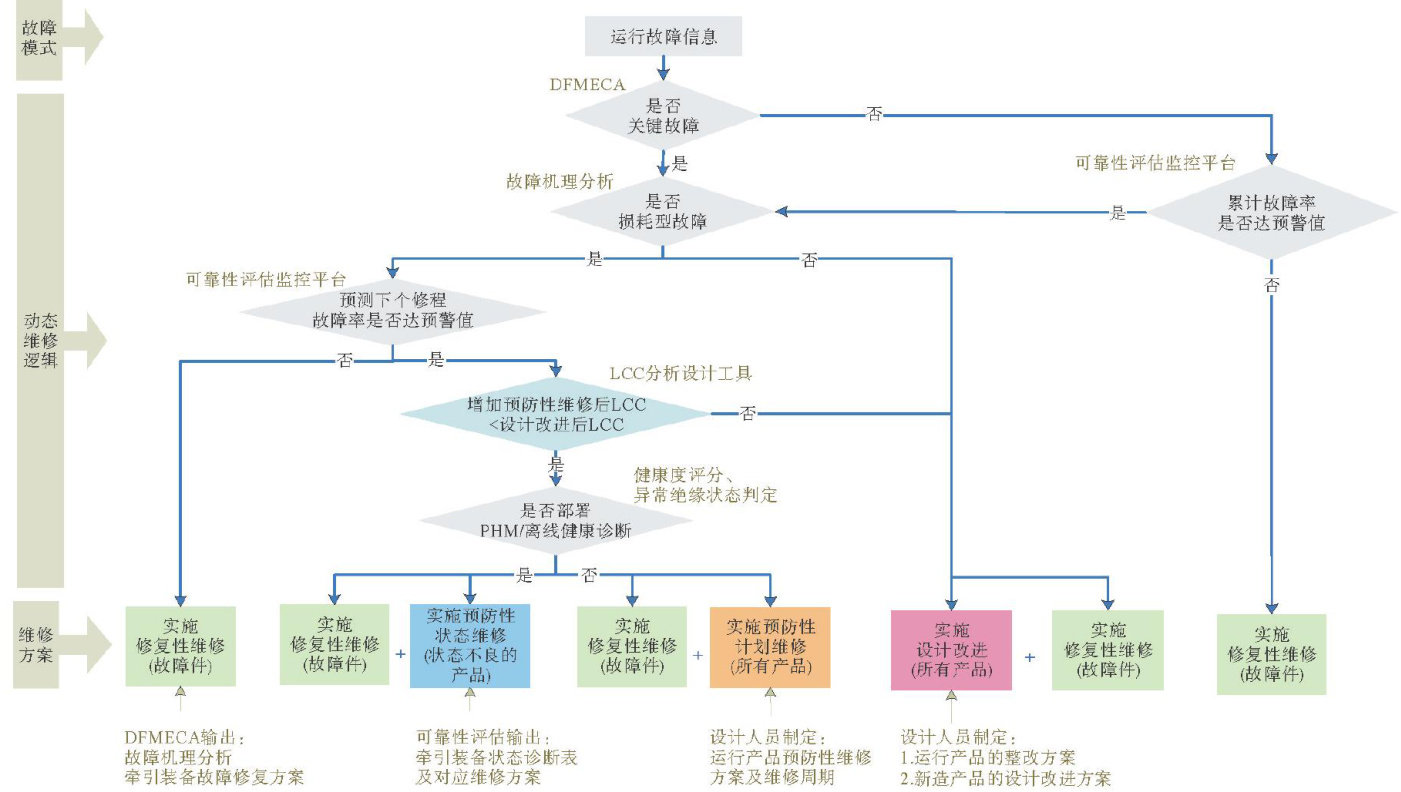

Abstract:The common maintenance mode used for the operation of current products presents the problems of over-maintenance or under-maintenance,which may lead to the loss of quality and the increase of maintenance cost.To solve these problems,the article proposes a“dynamic maintenance pattern” based on reliability centered maintenance(RCM).The basic method based on RCM determines the model of dynamic maintenance patern,and based on the reliability of products and systematically analyzes the modes,causes and effects of the faults of product.For diferent types of faults,using the methods of fault rate monitoring, faultrate curve acquisition,fault rate trend prediction,LCC evaluationand analysis,etc.,relevant maintenance strategy is proposed according to different circumstances such as whether there is the PHMor the off-line health diagnosis function.The logic decision method is used to judge the optimum maintenance solution for different types of faults of products,providing a scientific basis for establishing the preventive maintenance need and optimizing the classes of repair and the maintenance system. Based on this model,an indepth analysis has been conducted on the implementation methods of various logical judgment points,and an application example has been given by taking a certain type of motor product for an example. Through the application of this model,arapid and economical maintenance of the traction equipment can be achieved, further improving the reliability of the operation of equipment,enhancing the maintenance eficiency and reducing the life-cycle cost.

Key words:traction equipment;RCM;dynamic maintenance patrn;preventive maintenance;trend prediction

目前应用在国内铁路运输行业的牵引装备维修方式主要有2种:故障性维修,即出现故障立即修复;计划性维修,即依靠设计与维修人员的工程经验提前确定预防性修理计划,在现场检查或解体检修过程中批量实施。(剩余5144字)