基于超声波技术的铁路客车制动缸螺栓组拧紧工艺优化

打开文本图片集

中图分类号:U279.3 文献标志码:B doi:10.20214/j.cnki.zhgdjt.2025.02.013

Optimization of Bolt Group Tightening Process for Brake Cylinder of Railway Passenger Car Based on Ultrasonic Technology

CHEN Yan1,SUN Chao1,WANG Zhangyi²,WANG Chunsheng², CAO Yuan²,CHEN Yougen²,YANG Bo² (1. CRRC Nanjing Puzhen Rolling Stock Co.,Ltd.,Nanjing 21oo31,China; 2.School of Automation,Central South University,Changsha 4loooo,China)

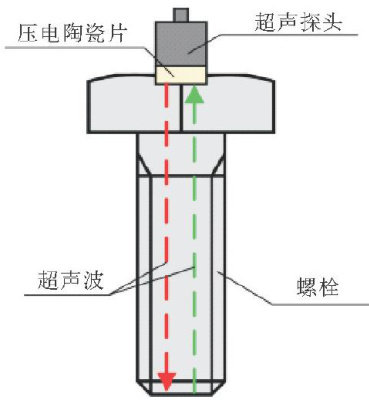

Abstract:To solve the problem of 0km air leak after maintenance of the unit brake cylinder of railway passenger car,the principle of measuring the pre-tightening force of bolts with ultrasonic waves is adopted to study the efects of diferent factors (high temperature,low temperature,vibrationand tightening process)on the atenuation of pre-tightening force of the bolt group for brake cylinder of railway passenger car,and the attenuation characteristics with different factors are used to optimize the adjustment of tightening process.In addition,the guidance of ASME PCC-2O22 Guidelines for Presure Boundary Bolted Flange Joint Assembly in the fastening process is verified and the current tightening process is optimized,adopting the process of tightening in steps and retightening. The result shows that the optimization of the tightening process allows to obviously slow down the atenuationof pre-tightening force,reduce the attenuation of pre-tightening forceof theunit brake cylinderand solve the problem of uneven distributionof pre-tightening force.These findings providea critical support for the maintenance of railway passenger cars and are expected to improve the performance and the reliability of the brake system of railway passenger car in the practical application.

Key words:railway passenger car;brake cylinder;bolt assembly;ultrasonic technology;optimization of ocess

近年来,铁路车辆的维修问题日益突出,其中制动系统的故障备受关注[1-3]。(剩余6837字)