基于SYSWELD的316L不锈钢T型试板焊后热处理数值模拟研究

打开文本图片集

中图分类号:TG405 文献标志码:B doi:10.20214/j.cnki.zhgdjt.2025.02.006

Study on Numerical Simulation of Post Weld Heat Treatment of 316L Stainless Steel T-type Test Plates Based on SYSWELD

WANG Jin1 ,PEIPeng²,WEI Wei³,YANG Xinhua³ (1.Operation Branch of Shijiazhuang Rail Transit Group Co.,Ltd.,Shijiazhuang O5oo35,China;

2.CRRC Tangshan Locomotive & Rolling Stock Co.,Ltd.,Tangshan O64099,China;

3.Liaoning Rail Transit Equipment Weldingand Reliability Key Laboratory,Dalian116o28,China)

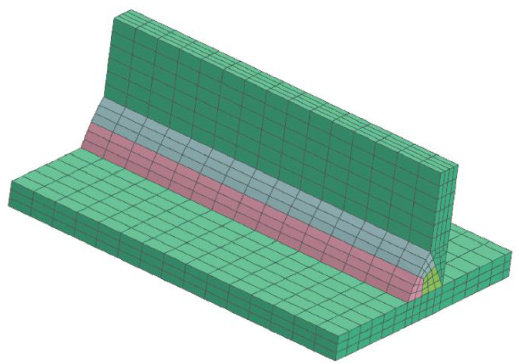

Abstract:This article takes 316L austenitic stainless steel as the object of study.By establishing a finite element mesh modelanda double-elipsoid heat source model for 316Laustenitic stainlesssteel,combined with the thermal elastoplastic theory and based on the SYSWELD software,the numerical simulation calculations were carried out on the welding processand the post weld heat treatment of the 316L austenitic stainless-steel T-type welded test plates.The residual stress distribution after welding of the T-type joints in the as-welded and heat-treated states was compared. The results show that:the established finite element model for simulation of welding alows to simulate the welding process and the post weld heat treatment of the 316L austenitic stainless-steel T-type test plates and get the distribution ofcorresponding temperature field and stress field;the transverseand longitudinal residual stresses of the T-type test plates in both the as-welded and heat-treated states exhibit a typical saddle shape,and the residual stressin the heat-treated state is higher than that in the as-welded state;compared with the deformation in the as-welded state,the overall deformation of the T-type test plates in the heat-treated state slightly increases.The relevant study may lay a foundation for predicting the residual stress of welding and the deformation of the 316L austenitic stainless-steel T-type test plates and optimizing the post weld heat treatment process.

Key words:numerical simulation of welding;residual stress of welding;316L austenitic stainless steel; T-type test plate;welding deformation

焊接是一个复杂的物理、化学作用过程,对其应变场和温度场的传统研究,多依靠试验观察和数据的统计分析[1-4]。(剩余6645字)