商用车电驱动齿轮疲劳寿命优化方法研究

打开文本图片集

中图分类号:U463 DOI:10.20042/j.cnki.1009-4903.2025.03.025

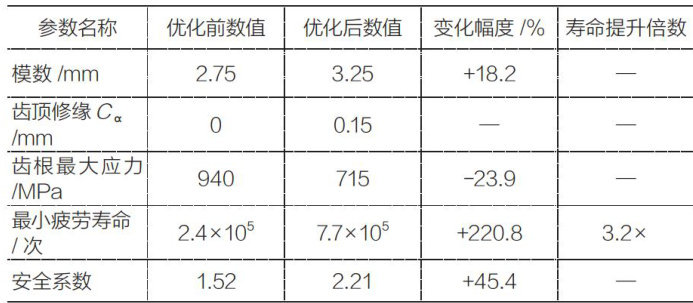

Abstract:Toaddress the issue of gear fatigue failure in the electric driveaxle transmission system of 6×4 electric heavy-dutytrucks underhightorqueandfrequentshitingconditions,thisstudyestablishesaloadinputmodelforrepresentativeoperatingcodions. BasedontheS-Ncurveof2OCrMTisteelandMiner’slineardamageaccumulationtheoryamuliconditionfatiguelifeevaluation method isdeveloped.Finiteelementsimulationsareemployed toidentifystress concentrationzonesatthegearroot,pinpointing regionsmostsusceptibletoftiguefailure.Subsequentlymutibjectivetructuraloptimatioapproachcombiningesponseuace methodologyadgeneticagoritisimplementedtofinegearmoduletoothumberratioandtipeliefoficent,trebyducing localstressandenhancingstructuraltrength.Benchtestsandrealroadtriasconfimthatheoptimizeddesignextendsgearfatigue life by 3.2 times,reduces gearbox noise by 4.6 dB,and lowers energy consumption per kilometre by 3.4% .The results demonstrate that theproposedptimizationmethodoffrssignificantengineeringeffectivenessandpracticalvalueinimprovinggearftigueresistance and overall drivetrain performance in commercial electric trucks.

Key words: Electric drive axle; Gear fatigue; Structural optimization; Finite element simulation; Heavy-duty truck

0 引言

随着新能源商用车技术快速发展,电驱桥已逐步取代传统动力系统成为 6×4 牵引类重卡的主流配置。(剩余5007字)