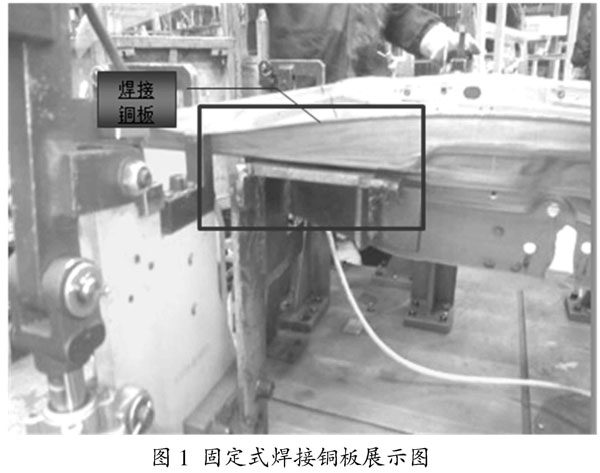

一种防止焊点漏焊的气动防错装置

打开文本图片集

摘 要:随着现代汽车技术的发展,客户对于汽车产品个性化的追求日渐强烈,导致白车身的车型不断增加,不同型号、配置共线生产成为现今汽车生产线的一种趋势。而零部件错装、漏装、漏焊成为影响白车身质量的重大因素。文章通过设计一种新型的气动防错装置,防止白车身漏焊、错焊,以保证白车身焊点的质量。

关键词:车身制造;漏焊;焊点;气动防错装置

中图分类号:U461.99 文献标志码:A 文章编号:2095-2945(2022)05-0104-04

Abstract: With the development of modern automobile technology and customers' pursuit of personalized automobile products, the number of body-in-white(BIW) models is increasing. Co-production with different models and configurations has become a trend of automobile production line. The wrong assembly, missing assembly and missing welding of parts have become major factors affecting the quality of BIW. In this paper, a new type of pneumatic error prevention device is designed to prevent missed welding and wrong welding of body-in-white, so as to ensure the quality of solder joints of body-in-white.

Keywords: body manufacturing; missed welding; solder joint; pneumatic error prevention device

一台白车身总成由上百个钣金零件逐级焊接而成,焊点数量在3 000~5 000点之间,电阻点焊和CO2保护焊是车身零件连接的主要方式,其中电阻点焊占总焊点数的90%。(剩余3118字)