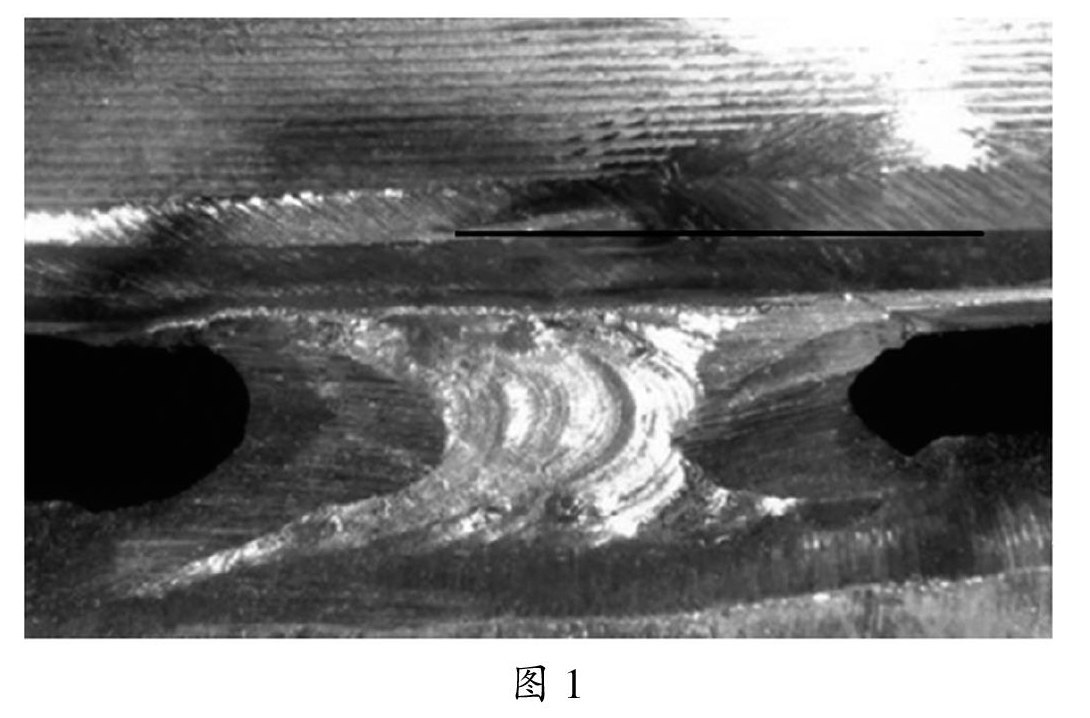

12Cr1MoV+35CrMo焊缝裂纹原因分析

打开文本图片集

摘 要:文章通过研究12Cr1MoV+35CrMo焊接方法和施工工艺,探究预热和热处理施工对中碳钢焊接的影响。经分析,预热和热处理施工流程可以有效地控制裂纹产生。在焊接过程中,因35CrMo热胀冷缩比12Cr1MoV快,易产生冷裂纹,通过正确预热和热处理,可有效地消除冷裂纹产生。

关键词:12Cr1MoV+35CrMo焊接;预热;焊接方法与施工工艺

中图分类号:TG44 文献标志码:A 文章编号:2095-2945(2021)04-0134-03

Abstract: By studying the welding method and process of 12Cr1MoV+35CrMo, this paper analyzes the influence of preheating and heat treatment on the welding of medium carbon steel. After study, the process of preheating and heat treatment can effectively eliminate the generation of cracks. During the process of welding, the thermal expansion and cold contraction of 35CrMo are faster than that of 12Cr1MoV, and cold cracks are easier to occur. Through proper preheating and heat treatment, the cold cracks can be effectively controlled.

Keywords: 12Cr1MoV+35CrMo welding; preheat treatment; welding method and process

1 概述

随着电力工业的快速发展,为了提高电力系统耐用性、持久性,降低投资,电厂系统采用的钢材不断更新换代,使用异种钢焊接不停增多。(剩余3413字)

网站仅支持在线阅读(不支持PDF下载),如需保存文章,可以选择【打印】保存。