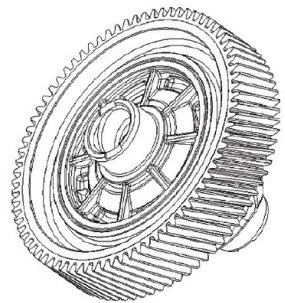

主减速从动齿轮内孔的感应退火模型研究

打开文本图片集

Abstract: In order to lightweight design anew energy main reducer assembly,we have adopted anew process route for the main reducer gear, that is, hobbing $$ carburizing quenching $$ induction annealing of the inner hole $$ fine inner hole $$ laser welding (and differential shell) $$ main reducer teeth. In this paper,the local induction annealing process of the inner hole of the product was studied,and the magnetic thermal coupling numerical simulation calculation was carredout by COMsOL finite element software,and the comparison and analysis were made with the test results, providing a new simple, eficient and reliable process model estimation method.

Keywords:main reducing gear; induction annealing;COMSOL

1序言

2 问题的提出

为了实现新能源减速器的高效传动,采用轻量化设计方案,即该减速器的差速器壳和主减齿轮采用激光焊接工艺代替螺栓联接。(剩余4697字)