原位热轧和热循环对电弧增材制造低合金钢微观组织和力学性能的影响

打开文本图片集

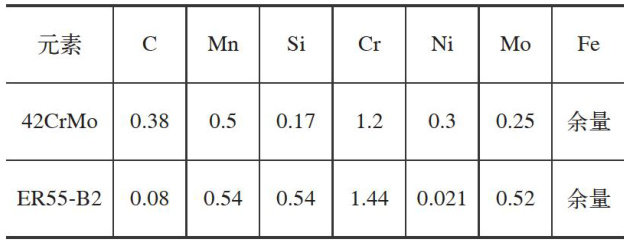

Abstract:Utilizing in-situhotrollng-assistedarcadditive manufacturing technology,this studyconductedadditive remanufacturing of motor shafts withlow-alloy steel wire.Through comparative analysis of single-layer and doublelayersamples,thestudyaimedtoelucidatetheeffectsofin-situhotrolingandthermalcyclingonthemicrostructure and mechanical properties of low-alloy steel.The results demonstrated that the microstructure without rolling was predominantly lath martensite. After undergoing roling,the lath martensite became fragmented and refined,and could further transform into tempered martensiteunder the influence of thermal cycling.The austenitic grains in the double-layer rolled samples were primarily equiaxed and exhibited characteristicsof discontinuous dynamic recrystallization.Compared to the single-layer rolled samples,the average grain size of the original austenite in the double-layerrolled samples wassignificantly reduced from 95.1μm to 32.8μm .Furthermore,in the dilution zone of the cladding layer of the double-layer rolled samples,a notable decrease in microhardnesswas observed.When comparing the roled samples to the unrolled samples,the tensile strength increased from 734MPa to 856MPa ,with a slight reduction in elongation.

Keywords:wire-arc additive manufacturing;in-situ roling; high-strength low-alloy steel; microstructure; mechanical property

1序言

轴向组件广泛应用于需要旋转运动、动力传输或结构支撑的众多行业和机械系统。(剩余5324字)