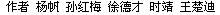

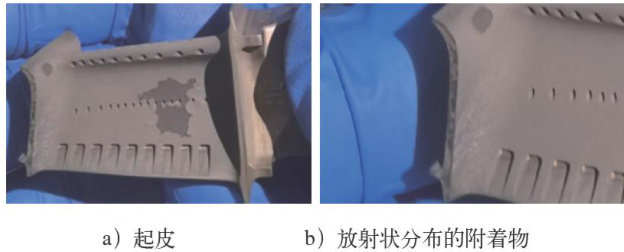

高压涡轮叶片表面起皮故障分析

打开文本图片集

Abstract:The working blades ofacertain engine's high-pressure turbine are made of nickel-based single crystal superalloy.To enhance their high-temperature corrosionresistance,theblade surface iscoated withaNiCrAlY + AINiY composite coating using arc ion plating technology.After the engine testrun,peeling occurred on the surface of the blade body.Through macroscopic and microscopic inspections,combined with the engine disassembly,an analysis was conducted onthe peling failure of the high-pressure turbine working blade surface.The cause of the failure was found to be wear and tear of the sealing coating on the inner side of the compressor working ring.The peeled coatingadhered to the blade's suction side after high-temperature oxidation,forming a grayish-black deposit.

Keywords: single-crystal turbine blade; arc ion plating coating; composite coating

1序言

镍基高温合金具有优越的高温力学及抗蠕变性能,已被广泛应用于航空航天、舰船及动力发电等领域,用以制造先进航空发动机、地面燃气发动机涡轮叶片等高温部件。(剩余4938字)